Nyutech provides high‑precision QR code laser marking solutions designed to deliver durable, accurate and high‑contrast marks on industrial parts, components, and products. Our laser marking systems support traceability, serialization, and identification in manufacturing, assembly, and quality assurance processes.

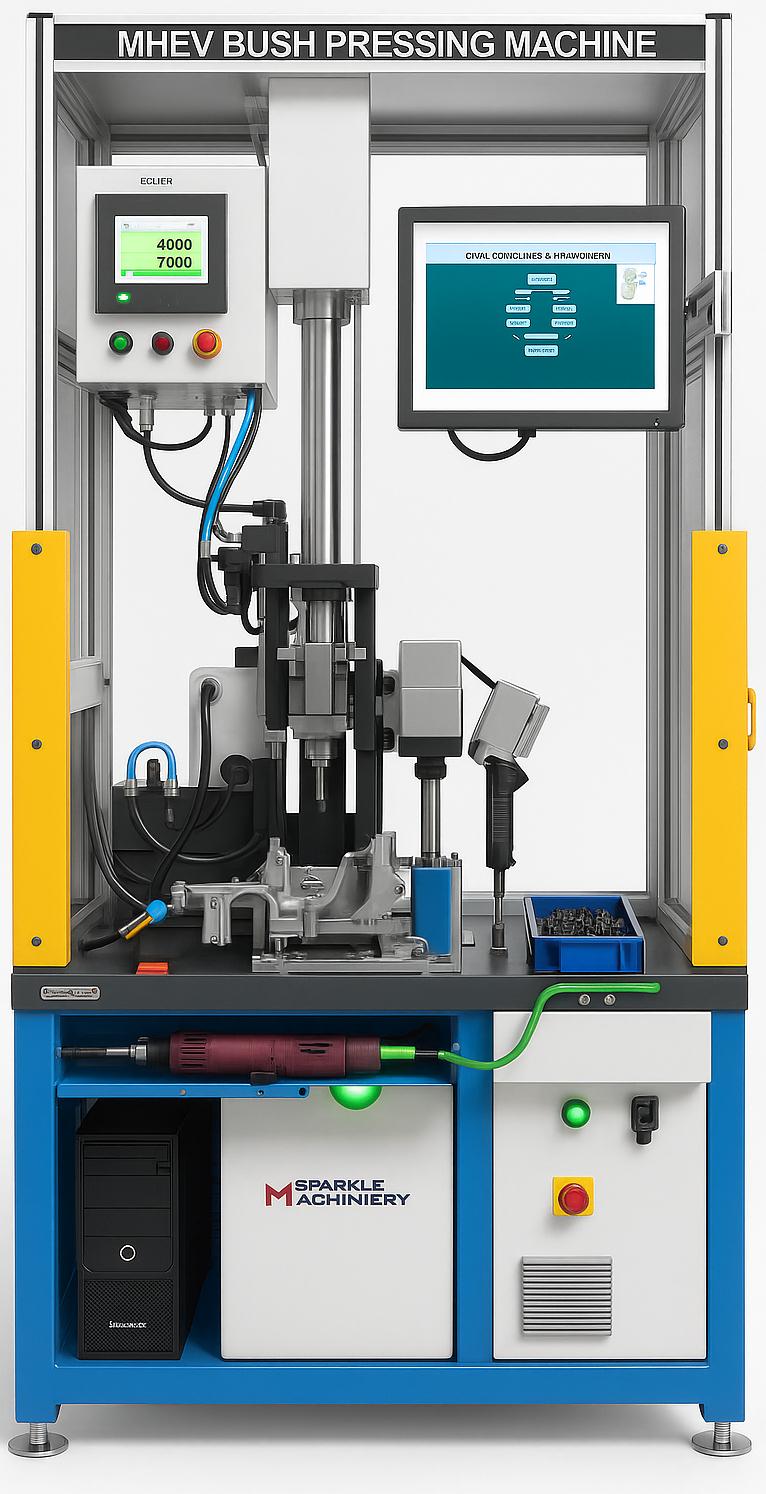

The MHEV Bush Pressing & Laser Marking System is a fully automated, intelligent manufacturing solution designed for precision assembly, real-time load and torque monitoring, and complete production data traceability.

It combines pneumatic press control, automated screw tightening, variant detection, and laser marking — ensuring total quality control and compliance with Industry 4.0 standards. System Overview

System Overview:

This machine performs bush pressing, screw tightening, and laser engraving operations on MHEV components in a single integrated cycle.

The pneumatic pressing system, equipped with a high-precision load cell, measures and records the applied pressing force, while the auto screwdriver captures torque and angle feedback for every fastener.

An Omron smart camera identifies the part variant, ensuring the correct operation sequence before proceeding to the marking stage.

All operational data is automatically logged in a centralized database for traceability and analytics.

Key Features:

System Benefits:

Application Areas: