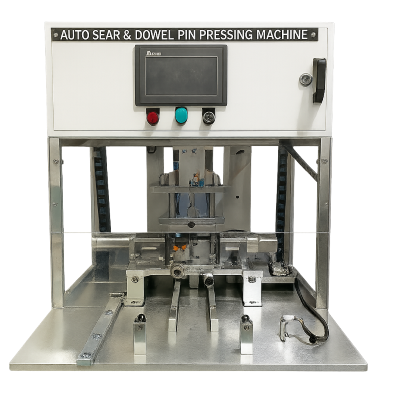

Auto Sear & Dowel Pin Assembly Machine

Auto Sear & Dowel Pin Assembly Machine

The Auto Sear & Dowel Pin Pressing Machine is an advanced semi-automatic assembly system designed to assemble sear sub-components with high precision and repeatability. The machine handles the complex process of assembling bottom base, torsion spring, and P-cut dowel pin in a fully controlled environment. The major challenge of ensuring P-cut dowel pin orientation is addressed using a dedicated Poka-Yoke mechanism and P-cut dowel magazine, ensuring error-free assembly. Additionally, the system is designed with universal pressing capability to handle similar parts through quick-changeover fixtures.

Part Loading:

- Operator loads bottom base into fixture.

- Torsion spring is pre-positioned in the dedicated holder.

- P-cut dowel pin is supplied through a magazine with poka-yoke alignment.

P-cut Dowel Orientation:

- The poka-yoke mechanism ensures correct orientation of the P-cut dowel pin.

- Incorrect orientation is rejected automatically, avoiding assembly errors.

Assembly Pressing:

- Pressing head aligns over the part.

- Bottom base, torsion spring, and P-cut dowel are assembled in sequence.

- Pressing force & stroke are monitored in real time.

Cycle Completion:

- Assembled part is released from the fixture.

- HMI displays assembly OK / NOK status.

Changeover Capability:

- By replacing fixture plates and updating HMI settings, similar assemblies can be processed.

Key Benefits:

- Automated & error-proof assembly of complex sear components.

- P-cut poka-yoke system ensures 100% correct dowel orientation.

- Multi-component assembly with force & position control for quality assurance.

- Quick-changeover design enables universal application for similar parts.

- Operator safety ensured with guarded enclosure and dual push buttons.