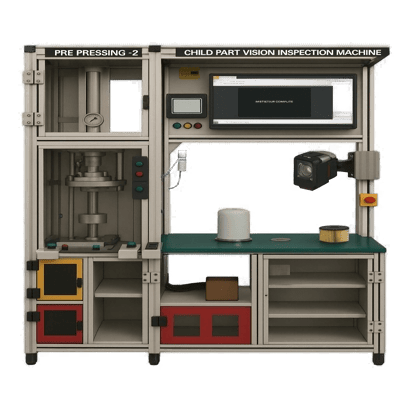

This dual-station machine is designed for precision pre-pressing and automated vision inspection of filter or component assemblies. It integrates a hydropneumatic press unit with load-cell feedback and a Keyence IV3-G500CA vision camera, ensuring consistent pressing force, dimensional repeatability, and visual confirmation of correct part assembly before downstream processes.

Core Features & Capabilities

- Dual-station design combining Pre-Pressing-2 and Vision Inspection functions.

- Hydropneumatic cylinder with load-cell feedback provides accurate force control and uniform pressing pressure across each cycle.

- Digital feedback loop for real-time force monitoring, stroke validation, and press position accuracy.

- Servo-regulated pneumatic logic with flow and pressure control valves for smooth operation.

- Pressing accuracy: ±0.05 mm, with programmable force limits to prevent part deformation or under-pressing.

- Vision inspection system with Keyence IV3-G500CA camera, angled for optimal focus on spin-on filter top surface.

- Smart vision tools for presence, orientation, and surface-defect verification.

- 7-inch HMI touchscreen for recipe selection, cycle data, and pass/fail indication.

- Pneumatic safety enclosure with dual push buttons and emergency stop.

- Real-time feedback of pressing force, stroke, and image inspection results to ensure process reliability.

- Tower lamp & buzzer indication for machine status, alarm, and cycle completion

Industry Use Case

- Ideal for::

- Automotive spin-on and cartridge filter assemblies.

- Pre-pressing of O-ring, gasket, and bonded joints before leak testing.

- EV motor housing and precision enclosure pre-fit operations.

- Tier-1 & OEM production lines requiring high-accuracy, traceable press operations

Connectivity & Reporting

- Compatible with MES / SCADA / SQL for real-time data exchange.

- Continuous load-cell and vision data logging (force, displacement, inspection results).

- Exportable CSV / Excel production summary reports.

- Optional remote diagnostics for pressure, camera status, and actuator feedback.

- Modular architecture ready for integration with robotic or conveyor-based automation systems

Child Part Vision Inspection & Pre-Pressing Machine

Child Part Vision Inspection & Pre-Pressing Machine