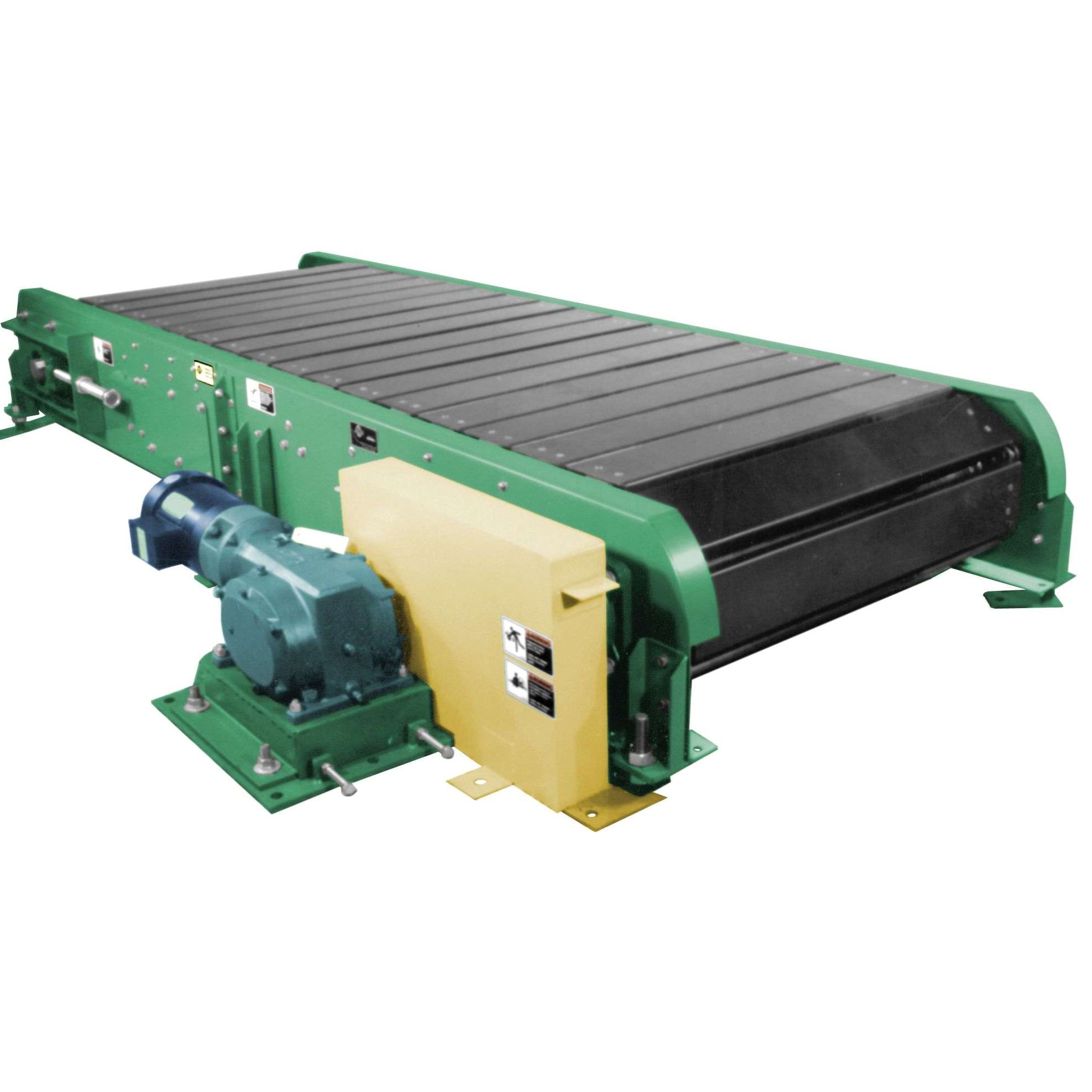

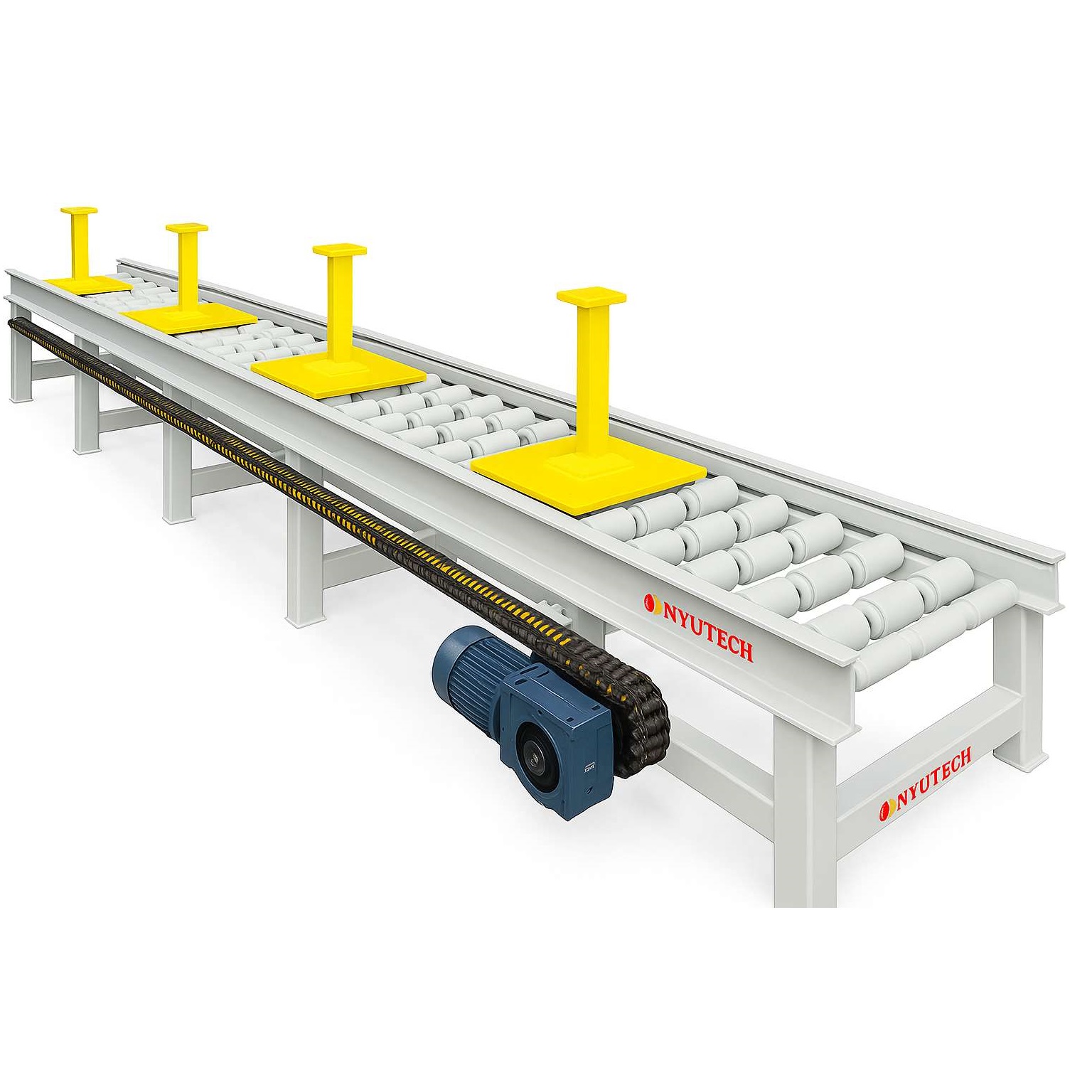

The Double Sprocket Roller Chain Conveyor is designed for medium to heavy-duty applications, ensuring reliable, synchronized, and smooth transfer of parts.

It employs dual side chain drives that power each roller through precision sprockets, enabling even torque distribution and consistent motion.

Driven by a geared motor with VFD control, it ensures variable speed operation, energy efficiency, and smooth acceleration.

This system can easily handle 5 parts at a time (10 kg each, total 50 kg) with stable conveying performance.

Key Features

- Dual-Sprocket Drive: Ensures uniform power transmission and stable conveying.

- VFD Control: Allows variable speed adjustment for different process requirements.

- Robust Construction: Heavy-duty powder-coated MS or SS-304 structure with leveling mounts.

- Precision Rollers: SS 304 rollers with anti-friction bearings for long life.

- Pneumatic Stopper: Optional mechanism for part positioning and accumulation control.

- Compact Drive Unit: AC motor with inline gear reducer for smooth operation.

- Easy Maintenance: Chain tensioners and quick-access design for roller replacement.

System Benefits

- Continuous and synchronized flow of components.

- Handles 5 parts × 10 kg efficiently (total 50 kg).

- Smooth operation with low vibration and noise.

- Fully compatible with PLC/HMI or robotic integration.

- Energy-efficient drive with high durability and minimal maintenance.

Application Areas

- Automotive and EV powertrain assembly lines.

- Metal and plastic component transfer systems.

- Machine loading/unloading conveyors.

- Testing and inspection automation cells.

- Industrial packaging and material handling.