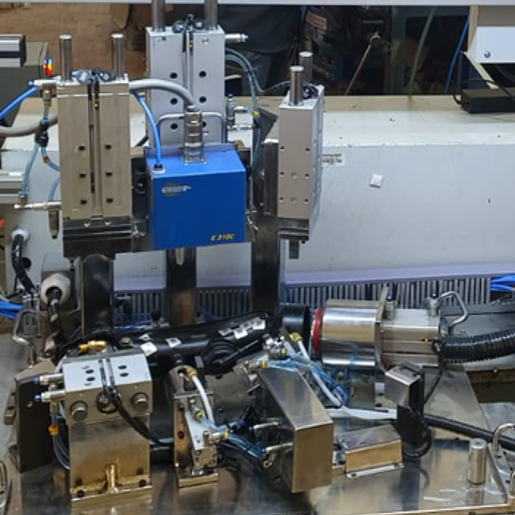

Nyutech provides dot pin marking solutions designed to deliver permanent, clear, and high-accuracy markings on industrial parts, components, and tools. Our dot pin marking systems support traceability, serialization, and identification in manufacturing and quality control environments.

Dot pin / dot peen marking is a robust, industry-proven method for creating permanent identification marks directly onto metal or plastic surfaces using a stylus that indents discrete “dots” to form characters, logos, codes, or 2D matrix patterns. This method is widely used in automotive, aerospace, and industrial manufacturing for component traceability and identification.

How It Works:

A pneumatic or electromagnetic stylus (pin) repeatedly strikes the part surface, creating a pattern of small indentations (“dots”) that collectively form text, logos, or codes.

Marking depth, dot spacing, and speed are adjustable via controller or PLC to suit different materials and quality requirements.

Because the mark is mechanical, it is resistant to wear, paint overcoat, ing, and environmental stress.

Key Features & Advantages:

For example, the I-Mark I Series dot peen units support 3–5 characters per second and offer multiple mounting orientations for compact footprint integration.

SIC Marking systems emphasize producing tamper-proof, everlasting marks by using electro-magnetic actuation and offering variable depth settings.

Marking Quality & Inspection Criteria: