The ST-400 A Heating Oven Conveyor is a compact, yet high-performance thermal-processing system designed for uniform and controlled heating of components prior to assembly, curing, or stress-relief operations.

It integrates a high-temperature-resistant stainless-steel (SS 304) mesh conveyor belt with PID-controlled conduction heating elements, ensuring even heat transfer across all components.

The system supports a temperature range from 60 °C to 250 °C, with precise control and monitoring through a touch-screen HMI interface.

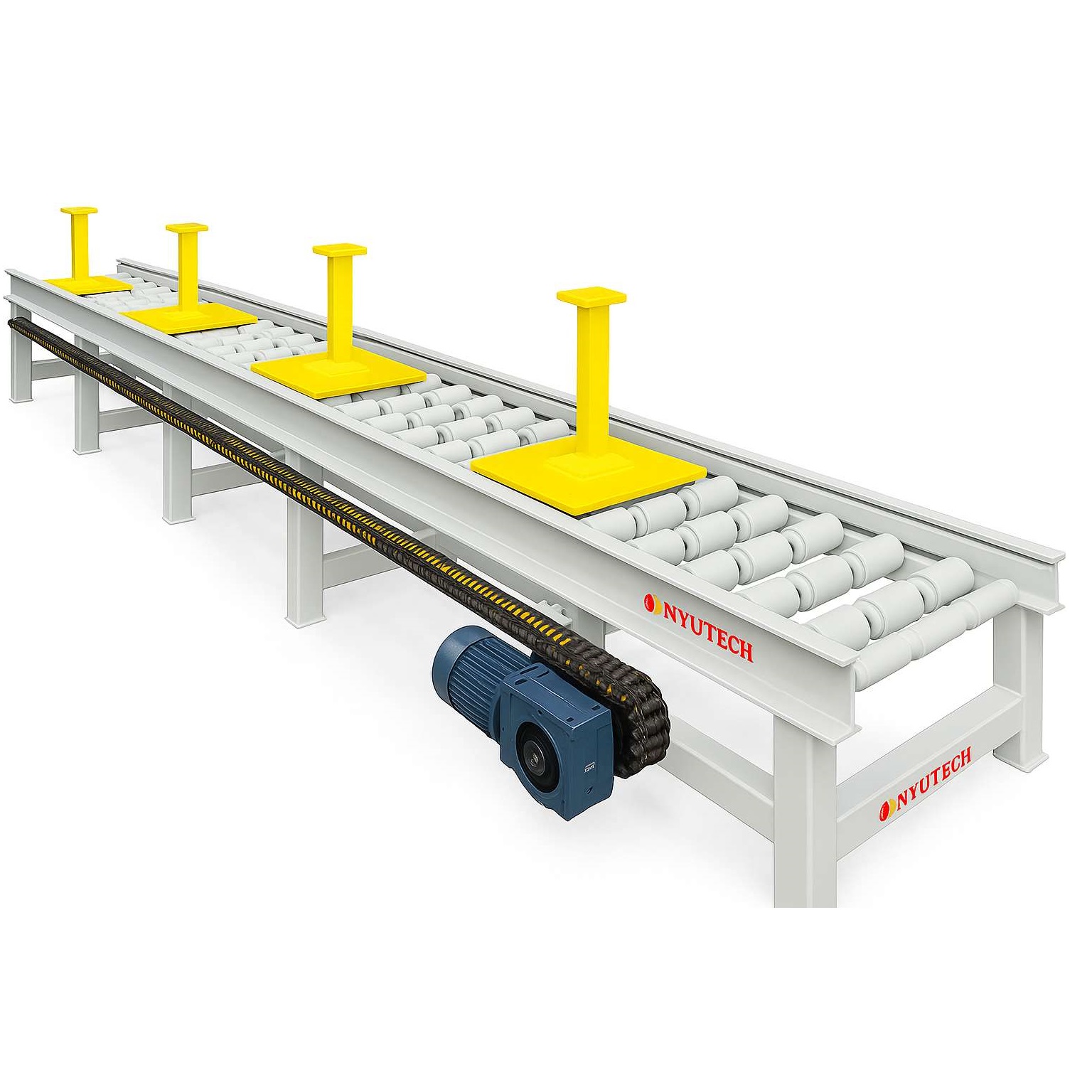

Material loading is configured for left-side entry and right-side discharge, enabling smooth inline connection with subsequent cooling, leak-testing, or inspection conveyors.

Technical Highlights

- Heating Type: Conduction / Radiant Heater System with insulated stainless-steel chamber

- Temperature Range: 60 °C – 250 °C (PID controlled, ± 2 °C accuracy)

- Belt Type: SS 304 woven mesh belt, heat-resistant up to 400 °C, non-deforming, low-friction surface

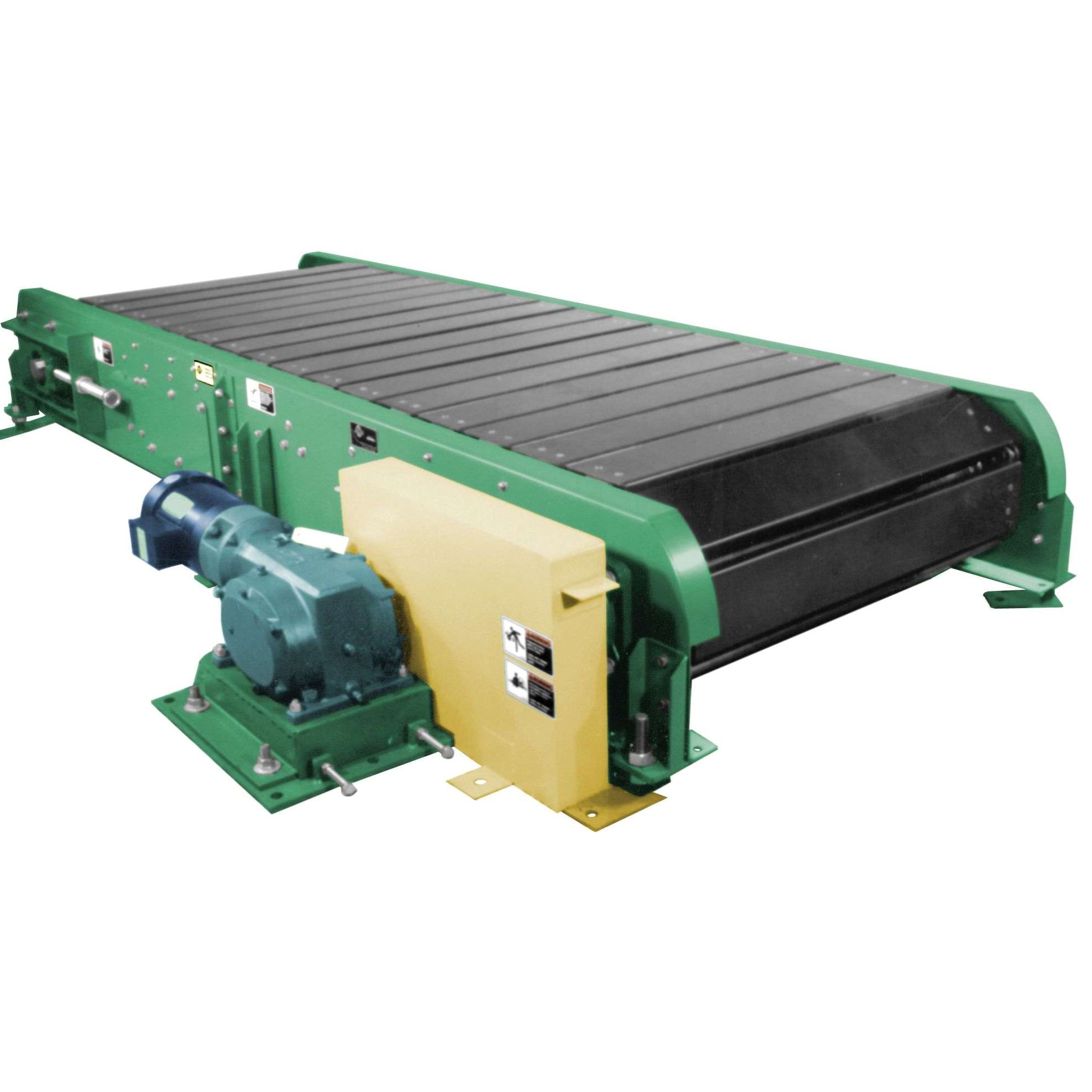

- Drive System: Heavy-duty AC induction motor with inline gearbox

- Speed Control: VFD (Variable Frequency Drive) for adjustable conveyor speed and dwell time control

- Frame: Rigid MS structure with industrial powder-coat finish for long-term durability

- Control System: PLC + HMI interface for temperature set-point, conveyor speed, and alarm management

Key Features

- Advanced Temperature Management – PID-based control ensures stable heating cycles and temperature uniformity.

- VFD-Driven Motor Control – Enables precise speed adjustment for variable dwell time applications.

- High-Temperature SS 304 Mesh Belt – Corrosion-resistant, heat-stable, and easy to for long service life.

- Modular Construction – Compact footprint with customizable lengths and heating zones.

- Integrated Controls – PLC and HMI with digital temperature display, fault diagnostics, and safety interlocks.

- Left Entry / Right Exit – Optimized for linear automation flow and synchronized handling.

- Smart Monitoring (Option) – Ethernet / Modbus TCP connectivity for data logging and traceability.

System Benefits

- Uniform and repeatable heating for precision components.

- Energy-efficient design with high thermal insulation and fast heat recovery.

- Reduced manual intervention and operator fatigue.

- Seamless integration with robotic and MES systems.

- Compact and service-friendly design for easy maintenance.

Application Areas

- Automotive and EV powertrain component heating and curing.

- Electronics and PCB thermal stress relief processes.

- Metal casting and heat-treatment pre-processing.

- Adhesive curing, epoxy setting, and paint drying.

- Food and pharmaceutical packaging sterilization.

- Robotics and automated production integration lines