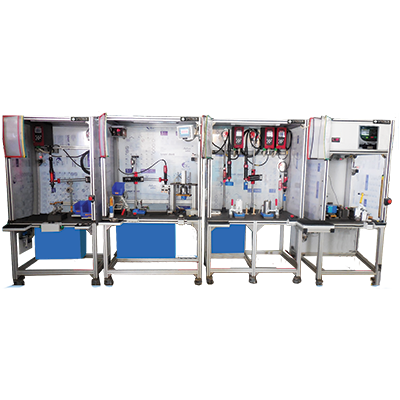

The Fuel Filter Assembly Line is a modular, semi-automatic / automatic assembly and end-of-line validation system engineered for high-precision automotive filtration components. It is designed to meet OEM & Tier-1 production standards, ensuring zero-defect output, flexible variant handling, and complete digital traceability.

Unlike conventional manual jigs, this system integrates intelligent pneumatics / servo-controlled actuation, Desoutter or Kilews torque system, and high-accuracy Poka-Yoke error-proofing, ensuring zero operator dependency and 24×7 production readiness.

System Capabilities

- Part Auto Loading & Orientation via sensor-based Poka-Yoke.

- Precision Pressing with pneumatic / hydro-pneumatic / servo actuation.

- Torque & Angle Controlled Screw Tightening (Desoutter / Kilews controller).

- Leak-Test / Vacuum / Flow Test (optional EOL Integration).

- Auto OK/NOK decision with pneumatic reject chute.

- HMI + MES connectivity for production history traceability.

- Auto & Manual Mode for operator safety and flexibility.

- Easy maintenance design | Tool-less fixture changeover.

Advanced Features

- Dedicated for 24×7 High-Volume Automotive Production.

- Supports Multiple Part Variants without Tool Change.

- Ensures Zero-Defect via 100% Poka-Yoke Inspection Logic.

- 100% Digital Quality Traceability — MES / ERP / Cloud Ready.

- Meets Global Standards — IATF 16949, VDA 6.3, ISO 16232.

- Industry 4.0 Ready — Barcode, RFID, Data Logging, Remote Diagnostics

Ideal For

- Fuel / Oil / Air Filter Assembly.

- EV Powertrain Component Assembly.

- Precision Automotive Plastic / Metal Housing Assembly.

- Tier-1 & OEM Quality Compliance Manufacturing

Fuel Filter Assembly Line

Fuel Filter Assembly Line

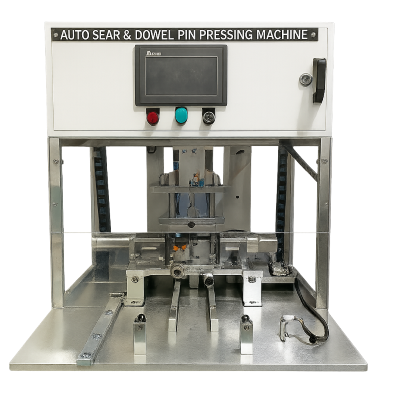

Auto Sear & Dowel Pin Assembly Machine

Auto Sear & Dowel Pin Assembly Machine