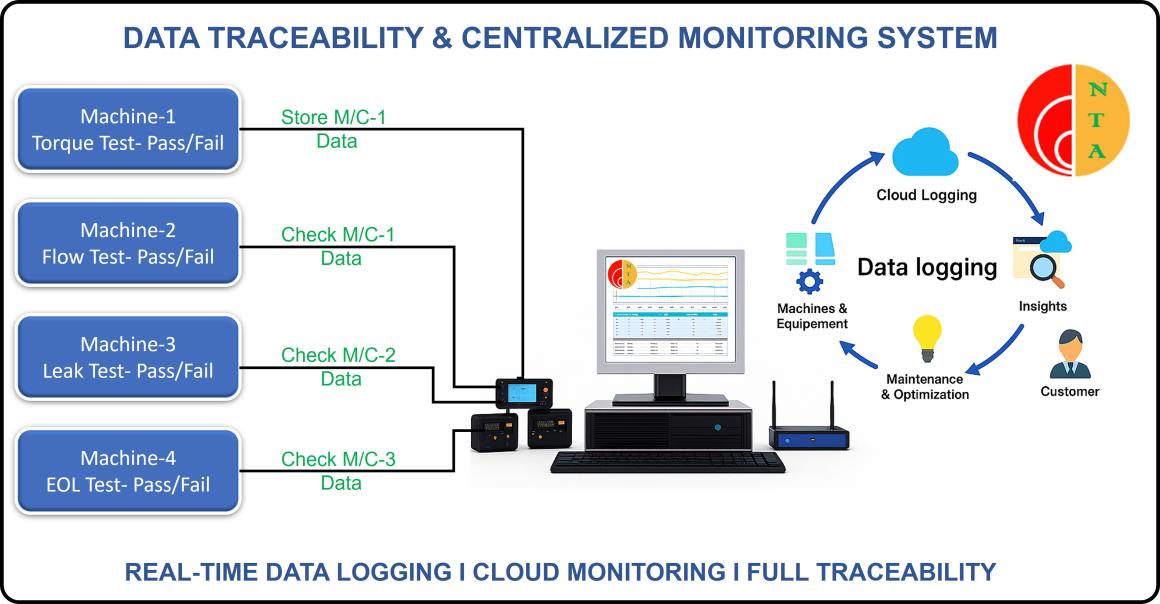

Nyutech’s process data storage solutions in Bangalore offer scalable and secure systems to capture, retain, and manage critical production and quality data across industrial automation environments. Designed for reliability and performance, our storage solutions support traceability, reporting, and analytics for manufacturing operations.

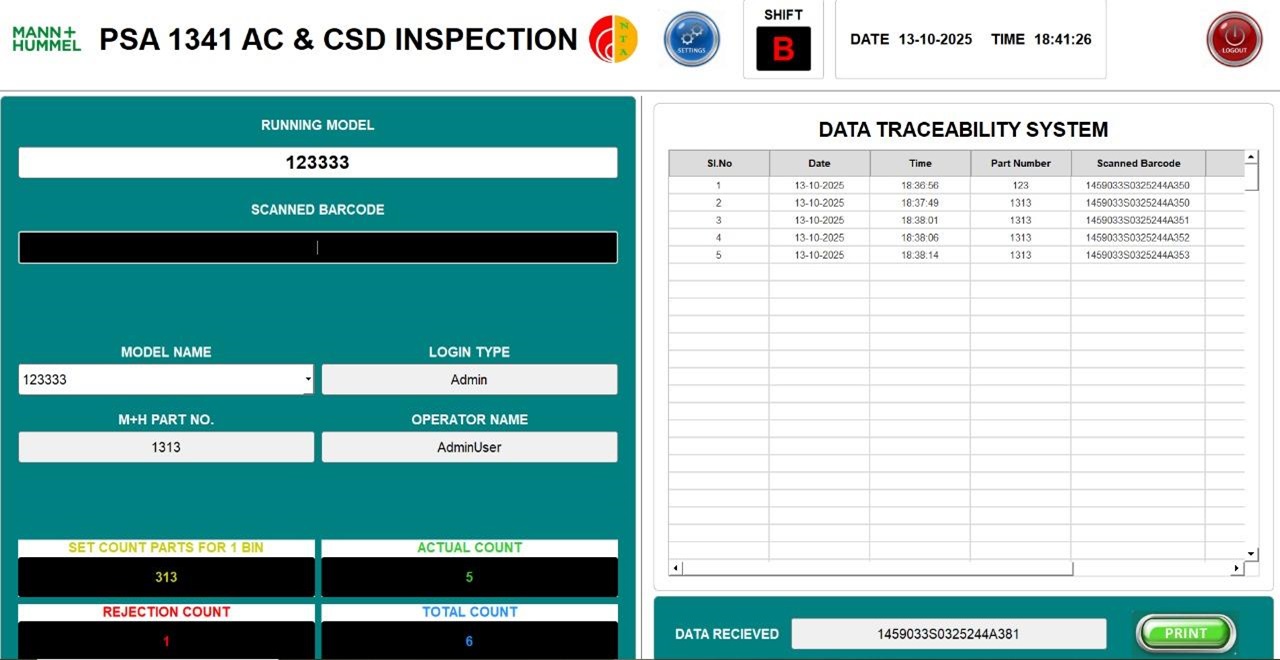

The PSA 1341 AC & CSD Inspection System is a fully automated production data traceability and quality assurance solution designed to validate component functionality, ensure product conformance, and provide centralized test data management. This system integrates multiple inspection modules—covering O-Ring presence, Plastic Ring presence, and Acoustic Cover verification—while logging real-time results for every part tested on the production floor.

System Overview:

Each inspection station communicates with the main server through Modbus TCP or Ethernet connection, providing seamless synchronization of all test data. The system automatically records all inspection results, timestamps, and barcode information, ensuring 100% digital traceability of the product’s test lifecycle.

Data is securely stored on a centralized server with CSV and database-level export support for audits and analytics.

Key Features:

Process Data Storage

Process Data Storage

Process Data Storage

Process Data Storage