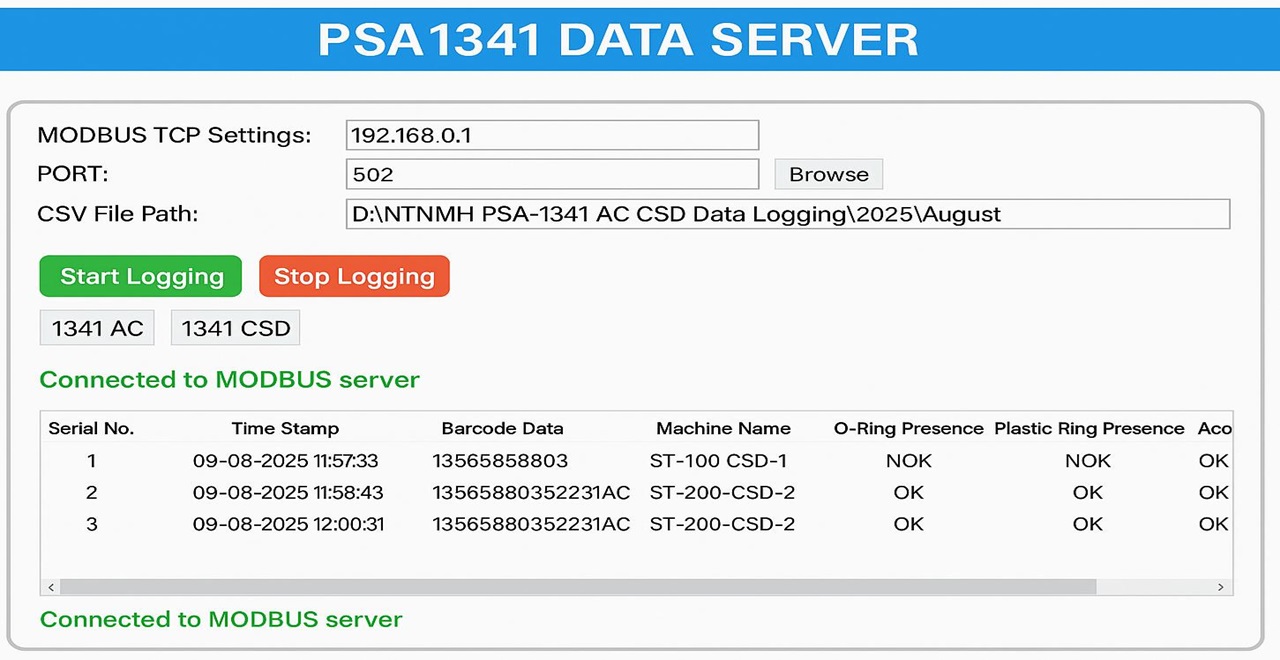

The PSA-1341 Data Traceability and Automation System is a fully integrated production platform designed to automate assembly, testing, and data capture across the Air er and CSD (Condensate Separator Device) manufacturing process.

System Overview:

It provides real-time visibility, machine-to-server data synchronization, and complete product traceability with automated Poka-Yoke (mistake-proofing) controls at every stage.

System Overview

The server logs all inspection data, including test results, thermal profiles, and barcode-based product identifiers, ensuring complete traceability across the entire assembly process.

Each test and assembly station — including Grommet Pressing, Screwing & Labeling, Completeness Checking, and CSD Leak Testing — communicates with the central data server over Modbus TCP or RS-485.

All process results, operator IDs, and barcode data are automatically logged and stored in a secure CSV/SQL database.

The system ensures 100% quality verification of all units produced and eliminates manual recording errors.

Key Features:

- 1. Multi-Station Integration

- Supports synchronized communication across all PSA-1341 test benches:

- CSD-1 Grommet Assembly & Leak Test Station

- CSD-2 Completeness Checking Station

- CSD-2 Negative Leak Testing with Zebra Label Printing

- Final EOL Machine with Barcode Validation and Poka-Yoke Interlock

- All machines are networked to the main data server for centralized monitoring.

- 2. Centralized Data Logging

- Real-time collection of test results, timestamps, and barcodes.

- Automated data transfer from PLCs via Modbus TCP.

- Shift-wise performance reports and auto-backup.

- Secure storage in structured SQL/CSV databases for audit traceability.

- 3. Functional & Leak Testing

- Dual-stage leak test validation using ATEQ leak testers.

- Configurable vacuum/pressure test modes for CSD components.

- Auto-result classification (PASS/FAIL) and digital signature logging.

- Integration with Zebra printer for automatic traceability label generation.

- 4. Intelligent Monitoring & Poka-Yoke

- Real-time dashboards for test status and machine health.

- Process interlocks prevent operation without barcode scanning or correct part placement.

- Visual and buzzer alarms for NOK conditions.

- Operator authentication and shift identification for accountability.

System Benefits:

- 100% digital traceability of all test data.

- Zero operator dependency for data entry.

- Instant OK/NOK decision and data backup.

- Seamless communication with main Modbus data server.

- Compliance with IATF 16949 / ISO 9001 automotive quality standards.

Application Areas:

- Air er and CSD module assembly lines.

- Leak and functional testing for plastic and aluminum housings.

- Barcode-based end-of-line traceability systems.

- Automotive component production with data analytics integration.