The ST-400 C Cooling Conveyor is designed to provide efficient part cooling after heating, molding, or thermal-stress operations. It uses a stainless-steel roller bed and axial-flow blower fans mounted inside the upper housing to ensure uniform air circulation and rapid heat dissipation from components as they pass through.

The system integrates with upstream and downstream modules via industrial Ethernet or Modbus TCP, ensuring seamless data exchange, automatic temperature logging, and synchronized cycle operation.

Key Features

- Axial-Flow Cooling Fans – High-efficiency aluminum impeller fans mounted horizontally on the top enclosure for uniform airflow and consistent cooling performance.

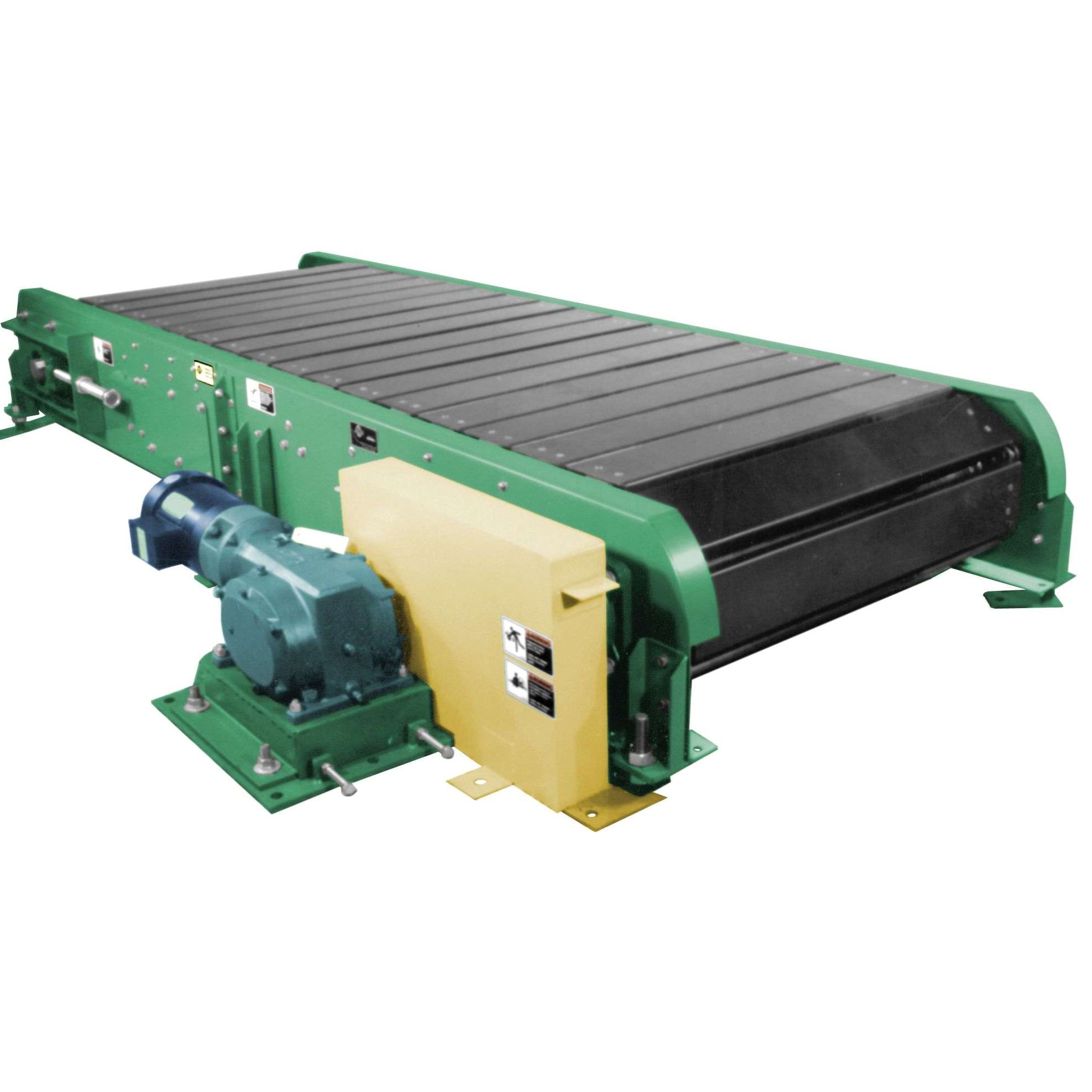

- VFD-Controlled Drive System – AC induction motor with inline gearbox drive for smooth, adjustable conveyor speed through a Variable Frequency Drive.

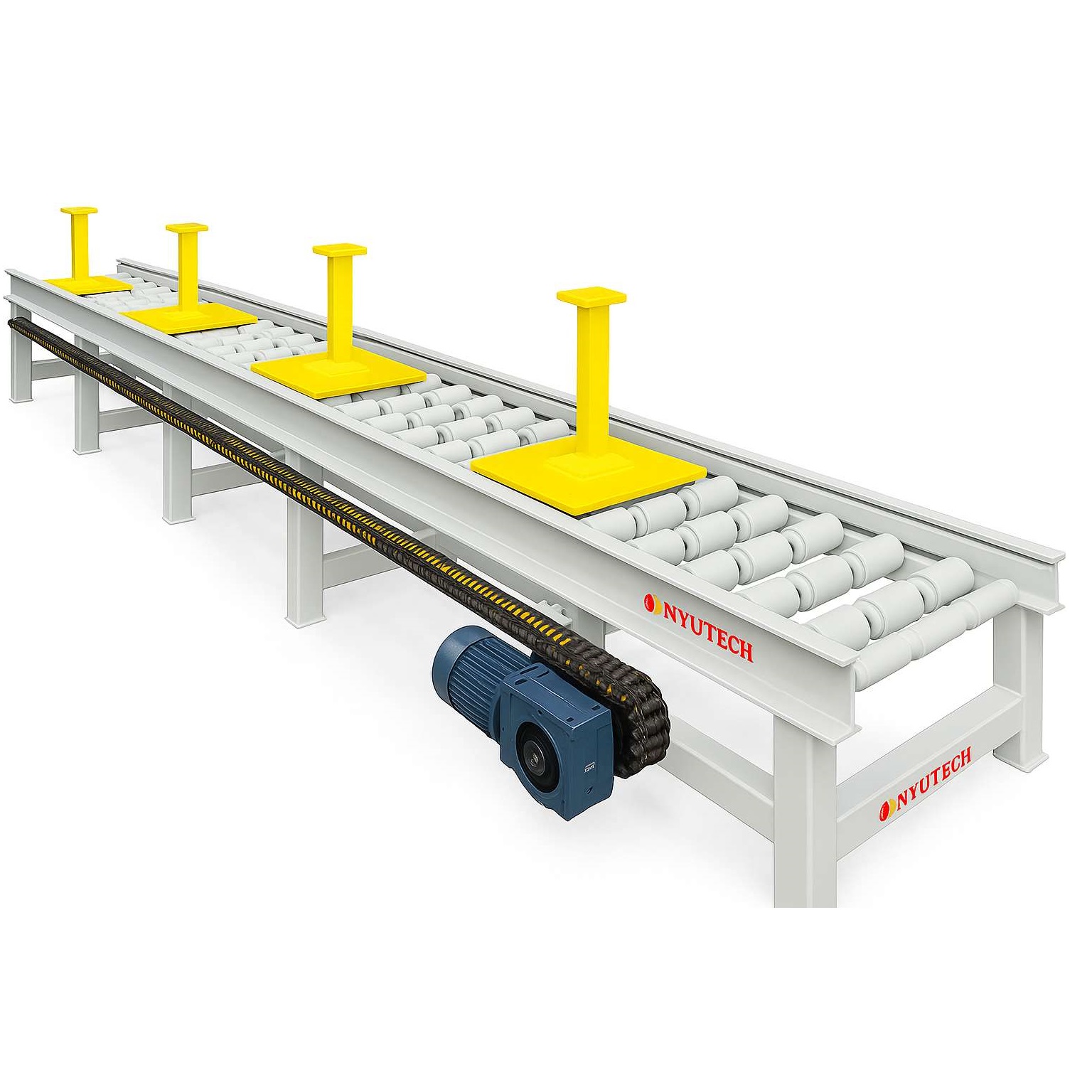

- Pneumatic Stopper Mechanism – Integrated air-cylinder-driven mechanical stopper allows precise part positioning for automated inspection or transfer.

- Modular Construction – Compact frame fabricated with powder-coated steel and stainless top rollers for corrosion resistance and easy maintenance.

- Integrated PLC & HMI Controls – Real-time display of conveyor speed, temperature, and fan status, with interlocks for upstream/downstream automation.

- Safety & Ergonomics – Transparent polycarbonate front door with handles for operator visibility and protection; emergency stop and pneumatic FRL unit for air regulation and safety compliance.

- Smart Monitoring (Option) – Provision for IoT modules to record temperature, motor load, and airflow diagnostics.

System Benefits

- Rapid, uniform part cooling with energy-efficient airflow.

- Adjustable conveyor speed with VFD control for different product dwell times.

- Reliable, repeatable cooling between heating and inspection processes.

- Compact footprint suitable for in-line automation.

- Reduced operator fatigue and improved process safety.

- Seamless integration with robotic handling and MES systems.

Application Areas

- Automotive & EV powertrain cooling modules.

- Electronics & PCB testing stations.

- Plastic and rubber molding lines.

- Heat-treatment and forging processes.

- Food & pharmaceutical component cooling.

- Automated inspection and assembly lines