Nyutech provides data traceability solutions designed to monitor, record, and manage production, assembly, and quality data efficiently. Our industrial traceability systems enhance process control, compliance, and productivity across manufacturing and automation environments.

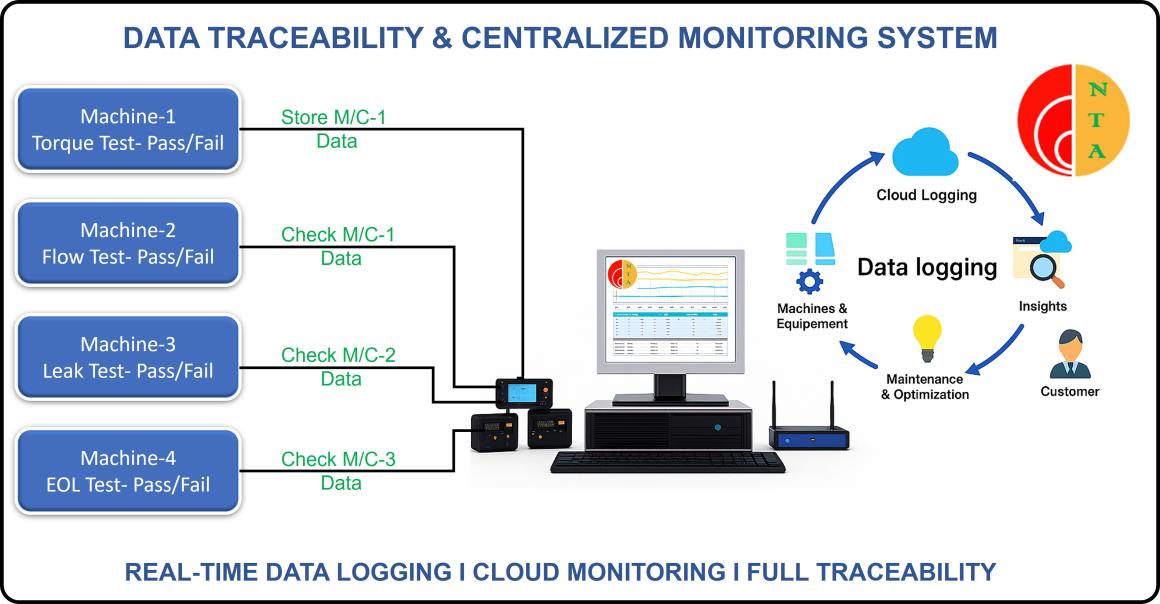

The NTA Data Traceability System is an integrated, real-time production data management solution designed to collect, analyze, and store test results from multiple end-of-line and sub-process machines across the manufacturing floor. It ensures complete product traceability, enhances process visibility, and supports data-driven quality decisions.

System Overview:

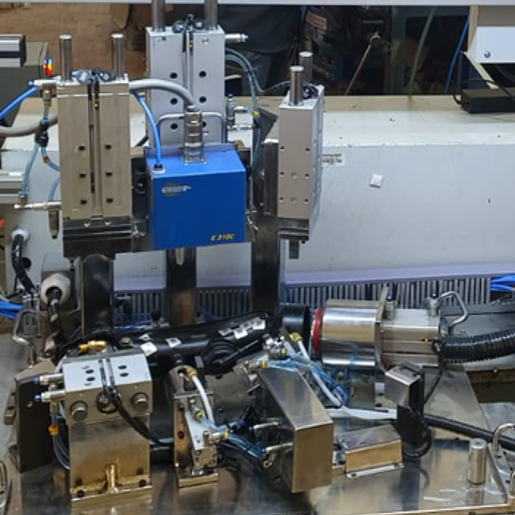

Each individual testing station — such as Torque Test, Flow Test, Leak Test, and EOL Functional Test — is networked to a centralized main server via industrial Ethernet or Modbus TCP communication. The server automatically logs Pass/Fail results, process parameters, and machine-specific data for every component tested.

This centralized data is then utilized for production analytics, process optimization, and quality traceability, ensuring zero data loss and real-time performance monitoring.

Key Features:

System Benefits:

Application Areas:

Data Traceability Solutions

Data Traceability Solutions

Data Traceability Solutions

Data Traceability Solutions