The Barcode and Traceability Identification System is a fully integrated labeling and marking solution designed for industrial manufacturing environments.

It ensures complete product traceability, process visibility, and data accuracy by linking every component or assembly with a unique 1D/2D barcode or QR code.

This system is compliant with global traceability standards such as AIAG B-17, ISO/IEC 15416/15415, ISO 9001, and IATF 16949, and forms a critical part of modern Industry 4.0 ecosystems.

System Overview:

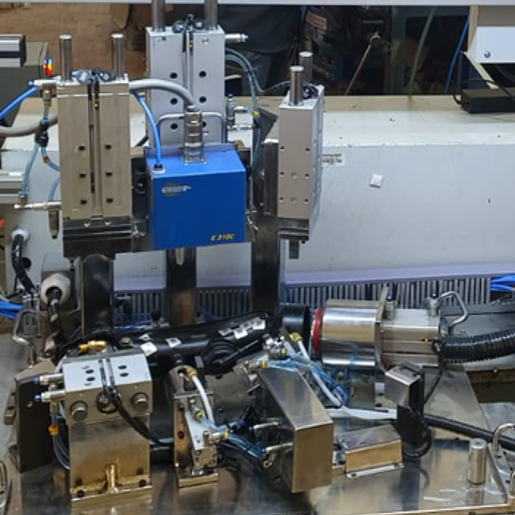

Each production or testing station is equipped with an automated label printer, barcode scanner, and traceability interface.

As soon as a part passes the inspection or test stage, the system generates and prints a unique label — containing part number, serial number, date code, and machine ID — and associates it with that specific test record.

These labels can be applied manually or via an automatic applicator, and later scanned during downstream operations or final assembly to verify product lineage and history.

Marking & Identification Methods:

Different marking technologies are selected based on application type, substrate material, and environment:

- 1. Dot Peen Marking (Permanent Mechanical Indentation)

- Used for metal components, housings, or brackets.

- Creates indented characters or DataMatrix codes directly on the surface.

- Key Brands: Technifor (Gravotech), Sic Marking, Telesis.

- 2. Laser Marking (Non-Contact Permanent Marking)

- High-contrast, permanent 2D/QR codes suitable for aluminum, steel, and coated materials.

- Offers zero consumables and no maintenance requirements.

- Key Brands: Keyence, Trotec, Han’s Laser, Trumpf.

- 3. Thermal Transfer Label Printing (Adhesive Labels)

- For plastic, composite, or painted parts.

- Compatible with a wide range of materials — PET, vinyl, polyester, Kapton.

- Key Brands: Zebra, TSC, SATO, Brady, Godex.

- 4. Dot Matrix or Inkjet Marking (High-Speed, Temporary)

- Used for cable, connector, or polymer marking where surface deformation is undesired.

- Key Brands: Videojet, Domino, Markem-Imaje.

Label Design & Content Standards:

- Zero operator dependency — fully automated inspection and marking.

- 100% digital traceability of pressing force, torque, and variant ID.

- Instant OK/NOK feedback and real-time analytics display.

- Scalable Industry 4.0-ready architecture for MES integration.

- Compliance with IATF 16949 / ISO 9001 production quality standards.

Application Areas:

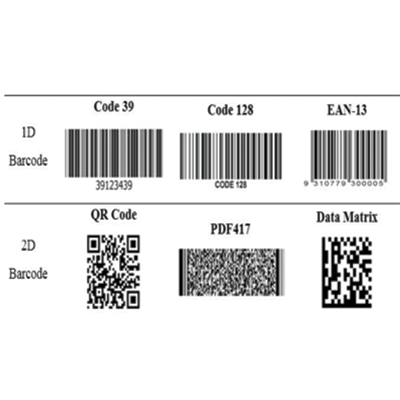

- Each label typically contains:

- 1D Barcode: Code 128 / Code 39 for line identification.

- 2D Data Matrix / QR Code: Encodes serial number, batch, and timestamp.

- Text Fields: Part name, station ID, date/time, operator ID.

- Logos / Compliance Marks: CE, RoHS, UL, or customer-specific symbols.

- All labels comply with GS1 Data Matrix and AIAG B-17 guidelines to ensure machine readability and audit-level traceability.

Key Features:

- Automatic label generation linked with machine test results.

- Integration with Modbus TCP / Ethernet-based data servers.

- Label print confirmation and scanner validation (Poka-Yoke).

- Support for multiple label formats (Avery, Brady, Zebra ZPL templates).

- Real-time database update for printed and verified parts.