Nyutech specializes in customized gauging machines designed to meet specific dimensional inspection and quality control needs. Our tailored measurement systems deliver precise, repeatable results and integrate seamlessly into manufacturing, automotive, aerospace, and industrial automation workflows.

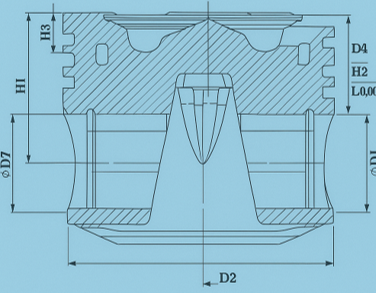

This automated gauging station is designed for high-accuracy inline inspection of engine pistons, using Baker-grade air gauging and digital contact probes to measure critical dimensions with micron-level precision. The system ensures 100% inspection, repeatability, and zero human influence, making it ideal for Tier-1/Tier-2 automotive OEM standards.

Key Dimensional Parameters Measured:

Technology & Features:

Advantages:

Key Dimensional Parameters Measured:

Piston Auto Gauging Machine

Piston Auto Gauging Machine

Customized Gauging Machine

Customized Gauging Machine