The EV-MCU Assembly Line Automation System is a fully integrated manufacturing solution designed to assemble, validate, and ensure 100% traceability of Electric Vehicle Motor Control Units (MCU).The system automates the entire process — from PCBA mounting and heat sink screwing to connector assembly, thermal stress validation, leak testing, and data logging — to guarantee process reliability, performance accuracy, and zero-defect quality output.

System Overview:

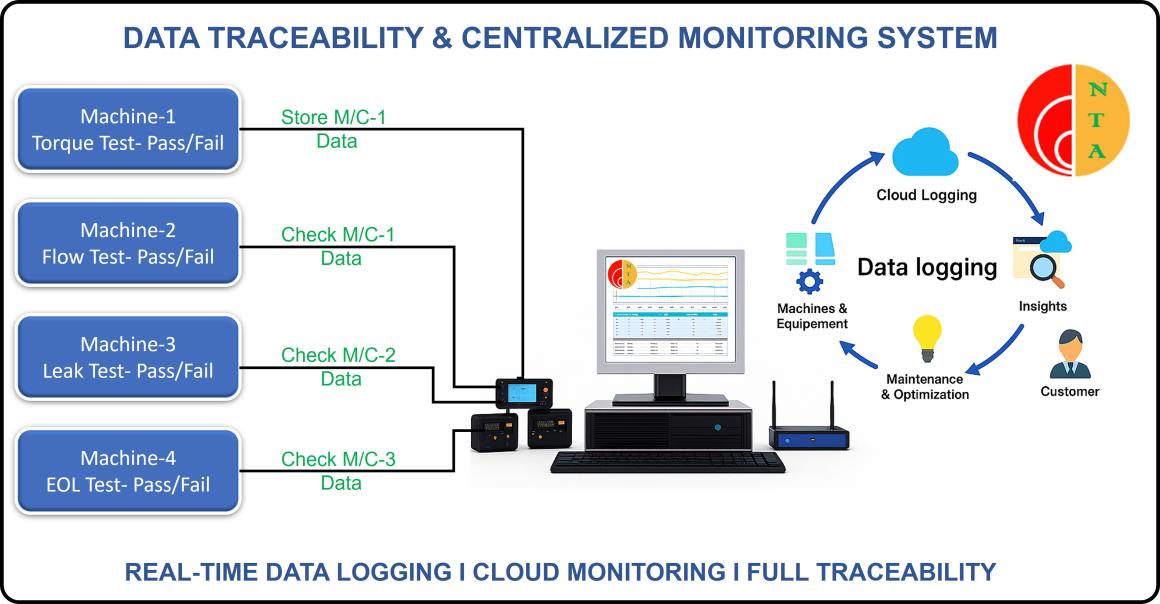

Each workstation — including Heat Sink Screwing, Connector Screwing, Glue Dispensing, Thermal Stress Testing, and Leak Testing — is integrated through Modbus TCP / Ethernet communication to a centralized data server.

The server logs all inspection data, including test results, thermal profiles, and barcode-based product identifiers, ensuring complete traceability across the entire assembly process.

All critical parameters, such as current, voltage, temperature, and pressure, are continuously monitored and recorded in real time for predictive quality control.

Key Features:

- 1. Automated Assembly Line Integration

- Multi-station line with synchronized operation flow.

- PLC-controlled automation for screwing, dispensing, and component validation.

- Inter-station communication for sequential process locking (Poka-Yoke).

- Automatic barcode scanning for part identification and data mapping.

- 2. Thermal Stress Testing Module

- Controlled 48V DC, 210A power source for load-based heating verification.

- Tests MCU endurance and heat dissipation under simulated field conditions.

- Integrated heating oven and cooling conveyor with temperature sensors.

- Auto-generated test cycle profiles stored with timestamp and operator ID.

- 3. Leak Testing & Validation

- Pressure-based and flow-based leak testing integrated with test jig.

- Automatic comparison of test values with LSL / USL limits.

- Real-time result display with “PASS / FAIL” indication per unit.

- 4. Centralized Data Traceability

- Each MCU’s complete test record (ST-100A to ST-500) logged in database.

- Automatic data transfer to server for consolidated storage and reporting.

- Live dashboard showing OK/NOK count, total test summary, and shift data.

- Secure storage of test data in CSV / SQL format with backup support.

- 4. Quality & Compliance

- Barcode/QR-code traceability for each MCU throughout the process.

- Conformance to IATF 16949, ISO 9001 quality standards.

- Compatible with Industry 4.0 smart factory integration.

- Audit-ready traceability reports and part history visualization.

System Benefits:

- 100% digital data capture from all assembly and test stations.

- Elimination of manual logging errors and process mismatch.

- Increased production throughput and test accuracy.

- Continuous thermal and leak data for reliability validation.

- Supports process analytics and long-term product traceability.

Application Areas:

- EV Motor Control Unit (MCU) Assembly & Testing.

- Power Electronics Thermal Validation.

- End-of-Line Functional & Leak Testing.

- Automotive Electronic Component Manufacturing.