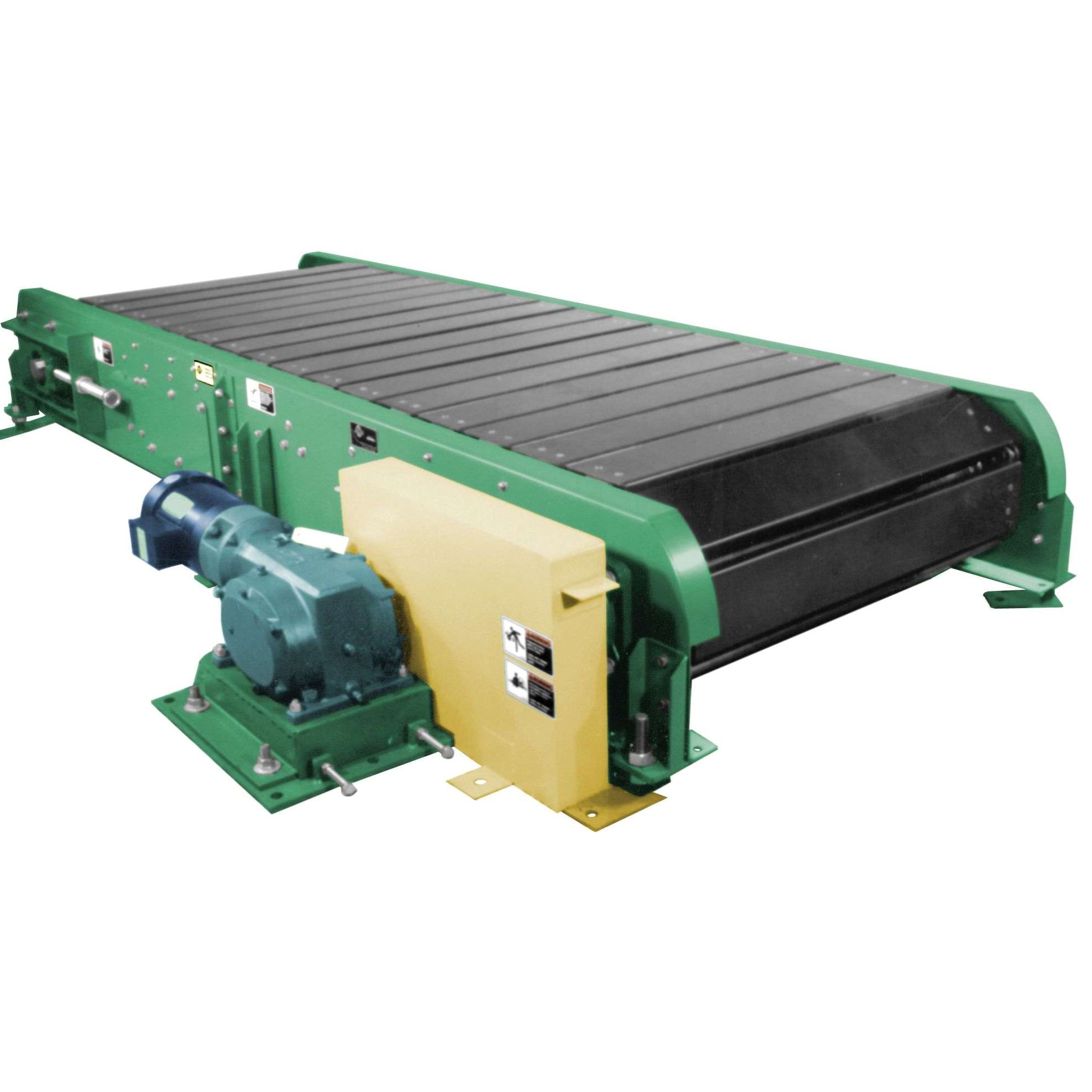

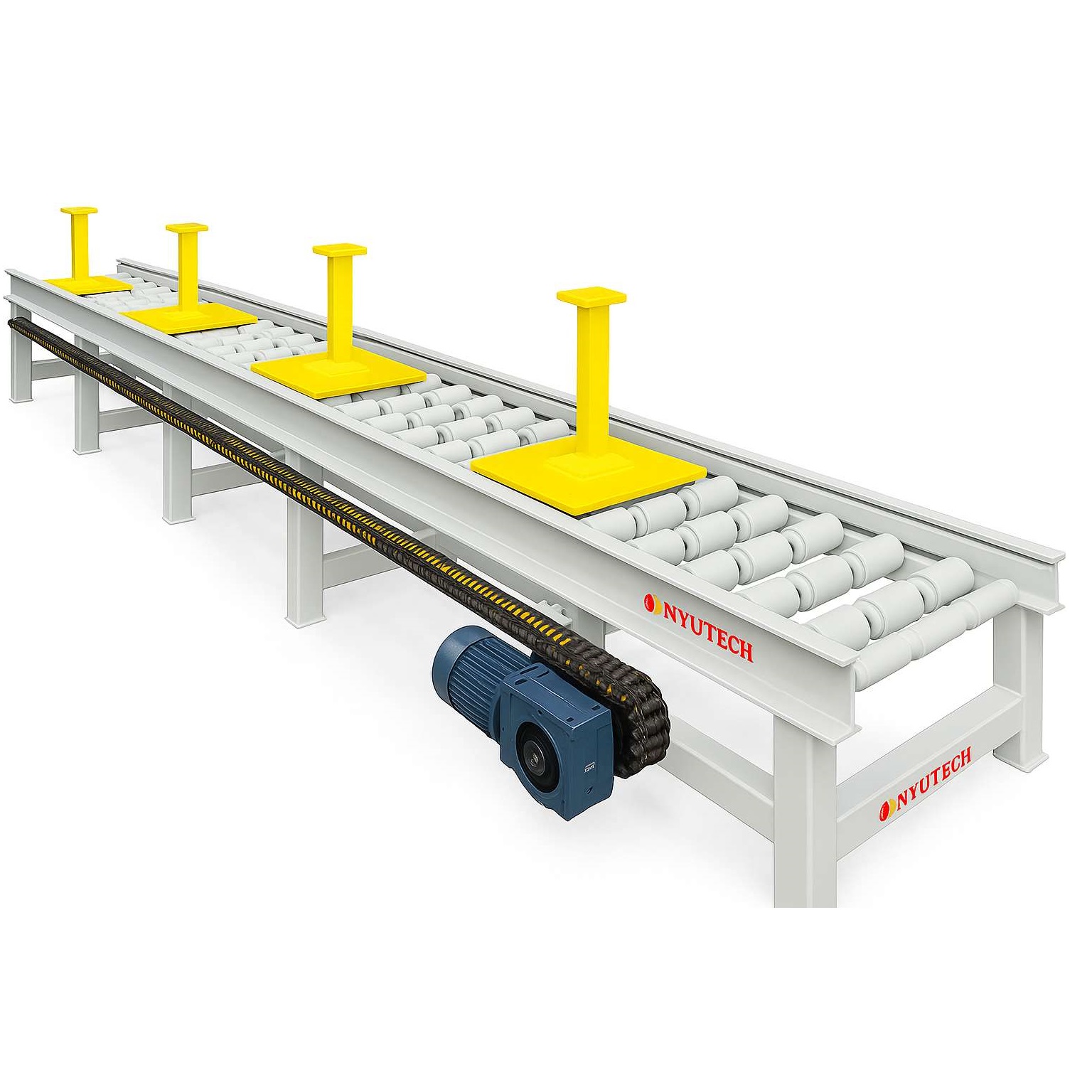

A slat conveyor is a type of conveyor in which material is conveyed on slats (flat plates) that are fixed to a chain or belt. The slats provide a rigid, flat surface to support parts of irregular shape or those that require stable carrying during transfer. Slat conveyors are ideal for high-precision transfer, indexing, or assembly operations, especially where parts cannot be directly placed on belt or roller surfaces.

These conveyors are widely adopted in assembly lines, automated handling systems, and production environments requiring robust, repeatable material movement without slippage or shifting.

System Architecture & Design

Slats

- Rigid plates (steel, aluminum, or high-strength plastic) mounted across chain links or a flat belt. Slats distribute load over a flat surface and prevent parts from sagging or tipping.

Drive Mechanism

- Typically chain-driven (e.g. roller chain, heavy-duty link chain), powered by a motor with gearing or servo system.

Guiding & Support

- Slats run on guide rails and side guides to maintain alignment. Under-slat support or wear strips ensure smooth motion.

Indexing Capability

- Often used in indexing conveyor systems—each slat moves in fixed steps, holding parts in specific positions for operations (e.g. machining or inspection).

Integration & Controls

- Controlled by PLC/HMI. Sensors detect slat and part position. Interlocks ensure safe operation with machine modules.

Modularity & Construction

- Frames built from modular aluminum profiles or welded steel. Slats or chains can be replaced digitally.

Environmental Suitability

- Suitable for room, painted, or heavy-duty industrial environments (with appropriate materials and seals).

Key Features & Benefits

High stability & precision

- Rigid support prevents parts from shifting or vibration—excellent for downstream processes.

Load distribution

- Slats distribute weight evenly across a larger surface — useful for heavy or irregular parts.

Selectable indexing

- Precise step-by-step movement to fixed stops for operations (e.g., presses, vision systems).

Customizability

- Slat sizes, spacing, and materials adapted to part geometry and environmental needs.

Long-term durability

- Suitable for harsh environments—use of corrosion-resistant materials or coatings.

Seamless automation integration

- Slat motion, part detection, and downstream machine control are synchronized via PLC/MES.

Application Areas

- Automotive / EV assembly lines (part orientation, handling)

- Indexing workstations (drilling, torquing, vision inspection)

- Painted or coated surface transfer (avoiding roller contact)

- Parts with irregular geometry (castings, housings)

- room or precise motion lines (electronics, semiconductors)