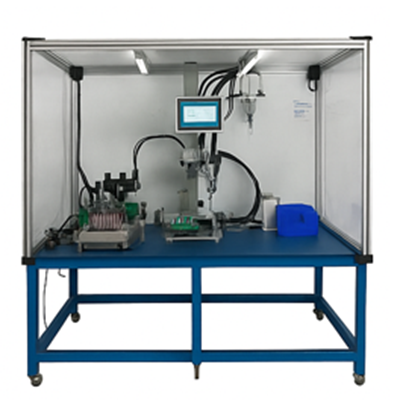

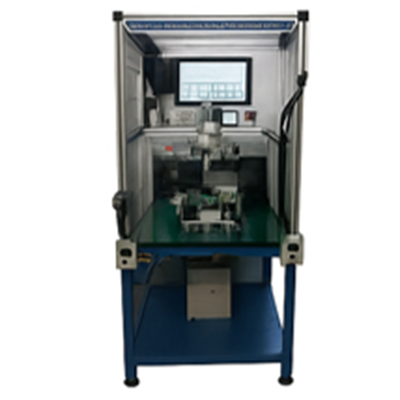

This system is an automated EV Motor Controller Assembly workstation designed for precision glue dispensing, online process validation, and complete data traceability.

Key Process Features:

- Automated PCB Positioning & Poka-Yoke for correct part loading.

- Servo-controlled robotic glue dispensing with precise path and volume control.

- Barcode / QR-code scanner for part identification.

- Auto OK/NOK decision with digital result generation.

- Industrial HMI with configurable glue path recipes.

- Automatic data logging to CSV / SQL / MES server.

- Robotic XYZ glue dispensing with ±0.1 mm bead accuracy.

- Path learning & recipe-based dispensing (supports multiple MCU variants).

- Auto PCB / part presence validation via sensors or vision.

- Auto barcode / QR recognition before dispensing (traceability interlock).

- OK/NOK classification based on volume, position & completion.

- Data logging to local database / MES / cloud (Industry 4.0 ready).

Why This System Is Preferred

- Fully eliminates operator dependency & glue wastage.

- Uniform sealing quality improves product lifespan & IP protection.

- Auto interlocked — rejects wrong part, wrong orientation, wrong recipe.

- Ready for EV inverter, ECU, BMS, smart controller sealing applications.

- Supports 24×7 high-volume automated production.

Benefits

- 100% accuracy and repeatability — eliminates operator dependency.

- Consistent sealing quality with programmable glue volume control.

- Ideal for EV control modules, inverter PCB, ECU sealing, relay/glow plug units.

- Supports Industry 4.0, smart manufacturing & MES connectivity.

- This robotic dispensing setup is designed for Tier-1 EV component manufacturers requiring precision, reliability, and traceable glue sealing automation.

PCBA Heat Sink Screwing

PCBA Heat Sink Screwing

Cover and Connector Screwing

Cover and Connector Screwing

Heating Oven, Thermal Stress & Cooling Conveyor

Heating Oven, Thermal Stress & Cooling Conveyor

Leak Testing and Data Traceability

Leak Testing and Data Traceability