The Power Window Symbol Vision & Illumination Inspection Machine is a high-precision automated vision inspection system designed to ensure accurate symbol marking and illumination quality of automotive power window switches. The system operates inside a controlled dark-room enclosure, eliminating external light interference, and utilizes servo-based motion control for repeatable and stable part positioning. Integrated with AVT and Basler industrial cameras, the system delivers ultra-high-resolution image analysis for flawless inspection of symbol engraving, laser marking, and LED illumination intensity.

Key Technical Features

- Vision & Illumination Inspection Technology.

- Equipped with Basler & AVT smart industrial cameras for precision vision inspection..

- Capable of verifying symbol accuracy, alignment, and clarity under multiple lighting conditions..

- Illumination intensity measurement through multi-stage image acquisition for white, amber, and dual-color LEDs..

- Dark-room setup ensures stable and uniform lighting, eliminating ambient reflection or glare..

- Servo-controlled fixture movement provides accurate part orientation during image capture..

- Configurable multi-angle inspection profiles for switch top, side, and backlight areas.

Inspection Method

- Automated image capture synchronized with servo axis motion for consistent repeatability.

- Real-time image processing to detect:

- Incorrect or missing power window symbols.

- Uneven or low illumination levels.

- Symbol color or intensity deviation

- Pass/Fail classification displayed instantly on the operator interface.

System Integration

- Inspection results displayed on industrial HMI and 21-inch HD monitor for real-time operator feedback.

- Data communication to PLC or MES system for traceability and batch analytics.

- Automated result logging and CSV / Excel data export for production records.

- Optional integration with robotic loading/unloading or reject chute for failed parts.

Mechanical & Ergonomic Design

- Compact dark-room enclosure with matte black interior to prevent light scattering.

- Servo-driven linear axis ensures smooth and accurate part positioning.

- Integrated diffused LED light source and adjustable brightness control.

- Ergonomic layout with easy access for component loading and maintenance.

- Safety interlocks, emergency stop, and light curtains for operator protection.

Applications

- Verification of power window switch symbol presence, orientation, and clarity.

- Illumination uniformity & color inspection for backlit symbols.

- Zero-defect visual quality assurance for automotive switch panels, HVAC buttons, and cluster indicators.

- Ideal for Tier-1 automotive interior part manufacturers focused on aesthetic and functional compliance.

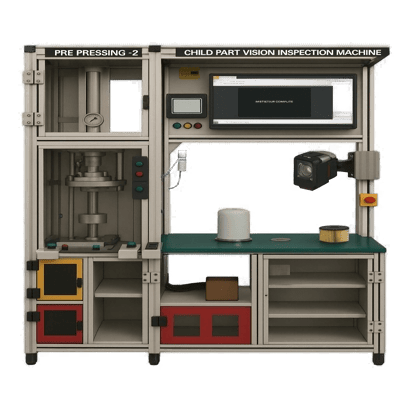

Child Part Vision Inspection & Pre-Pressing Machine

Child Part Vision Inspection & Pre-Pressing Machine