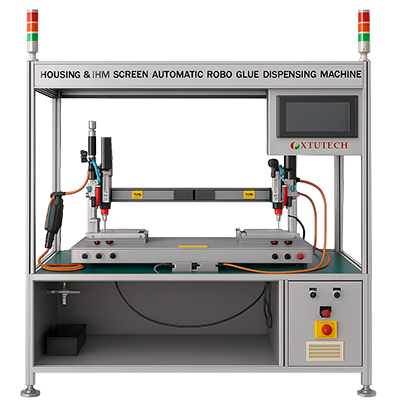

This is a fully automatic dual-station robotic adhesive dispensing system engineered for precision assembly of housings, plastic enclosures and mechatronic sub-assemblies. The machine features SCARA-type servo dispensing robots with programmable XYZ motion control, integrated process monitoring and real-time HMI visualization — ideal for Tier-1 / OEM electronics & automotive applications requiring repeatable high-accuracy glue application and zero-defect sealing reliability.

Core Features & Capabilities:

- Dual independent servo dispensing heads with programmable pattern control.

- Automated XYZ path movement with ±0.05 mm positional repeatability.

- Vision / sensor-based poka-yoke for part orientation & presence check (optional).

- 7-inch Delta touchscreen HMI for recipe selection, live status & error logs.

- Pneumatically controlled clamp fixtures to ensure precise part locking.

- Real-time alert via 3-color LED tower lamp & buzzer.

- Compatible with RTV, PU, silicone, epoxy & UV adhesives.

- Auto purge, needle ing & low-level glue warning system.

Industry Use Case (Ideal for):

- Automotive instrument cluster housings.

- EV control modules & smart energy devices.

- Communication device enclosures.

- PCB sealing, waterproofing & gasket replacement.

Connectivity & Reporting:

- MES / SCADA / SQL / Cloud-ready Industry 4.0 data architecture.

- Cycle time, glue quantity & traceability data logging (CSV / Excel output).

- Remote diagnostics & auto alarm for pressure, motion or adhesive fault.

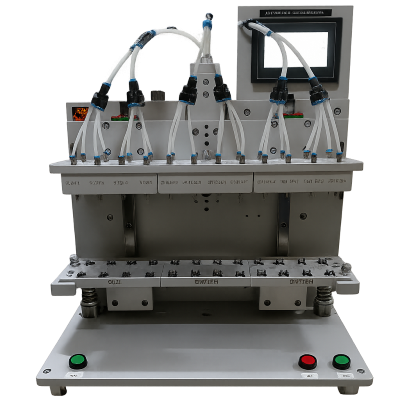

Dual Axis Auto Glue Dispensing Machine

Dual Axis Auto Glue Dispensing Machine