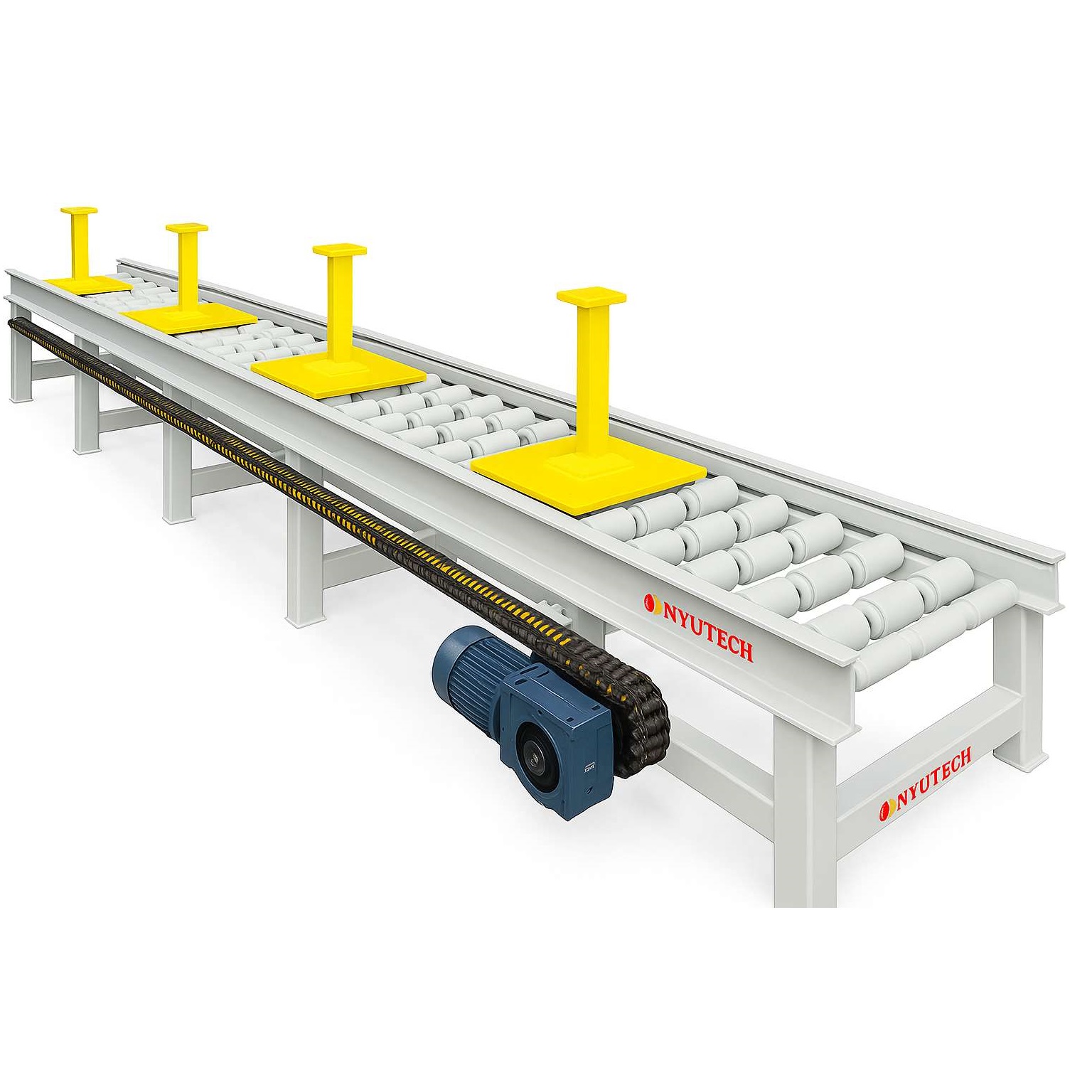

The U-Type Conveyor is designed for transferring products between parallel assembly or process lines, optimizing layout in compact spaces. The U-shape layout allows smooth directional change of materials (up to 180° turning radius) while maintaining consistent flow, indexing precision, and ergonomic handling.

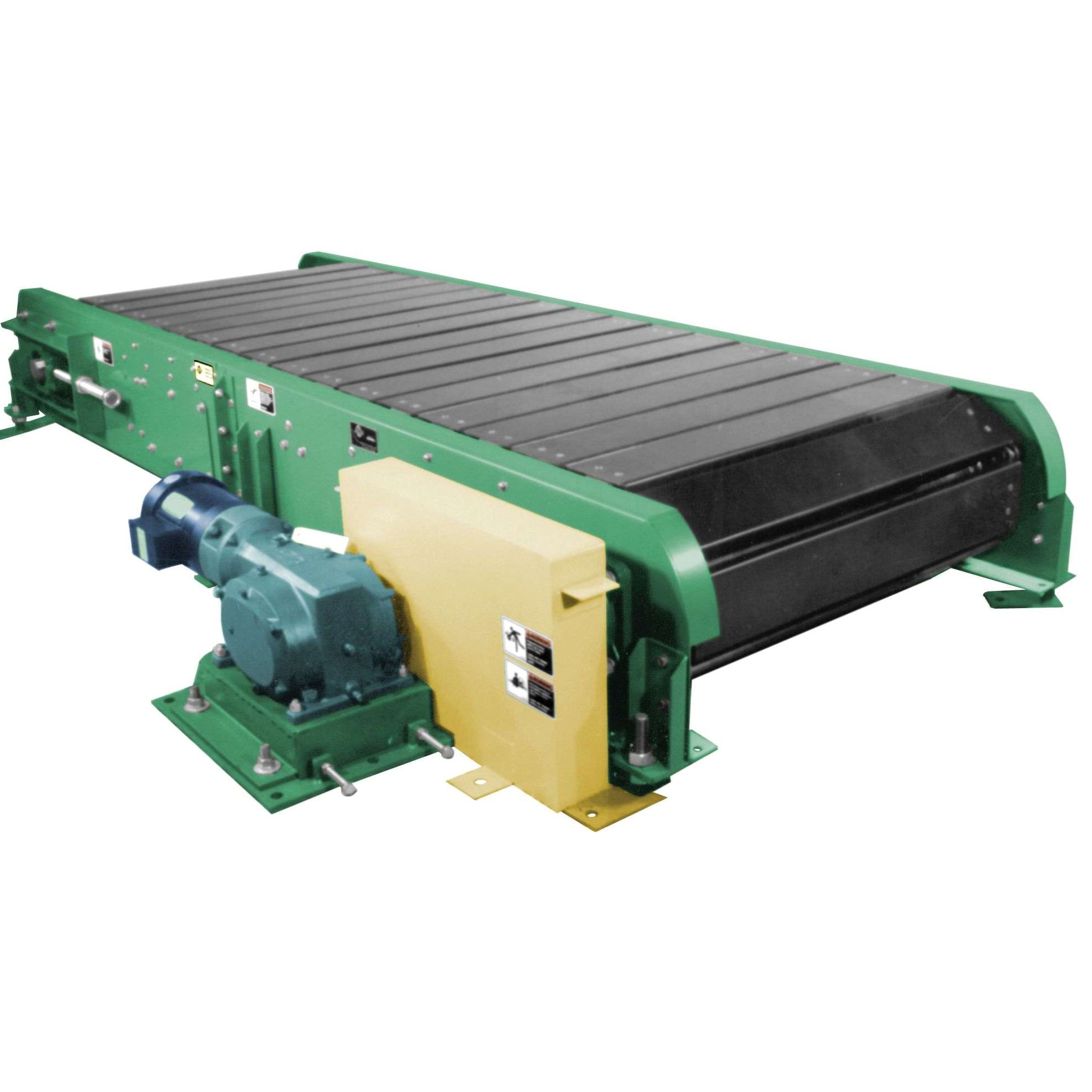

The system typically includes roller or chain-type conveyors, customized for product geometry, weight, and process requirements.

Each conveyor is powered by AC geared motor with VFD control for speed variation and process synchronization.

Key Features

- U-Shape Design: Enables space-saving configuration for return paths or interlinked process stations.

- Modular Construction: Easily extendable and reconfigurable design using robust MS or SS frames.

- Drive System: Heavy-duty motor with gearbox and VFD ensures smooth and adjustable speed control.

- Roller Assembly: Equipped with precision SS 304 rollers with anti-friction bearings for long service life.

- Integrated Controls: PLC + HMI system for speed adjustment, part detection, and automatic start/stop cycles.

- Mechanical Stopper: Pneumatically actuated stopper for accurate part positioning and safety interlocking.

- Safety & Ergonomics: Meets ISO 10218 and EN 619 safety standards with emergency push buttons.

- Scalability: Can be integrated with robotic cells, inspection systems, or manual workstations.

- Smart Monitoring: Optional IoT modules for motor speed, temperature, and conveyor health diagnostics.

System Benefits

- Smooth and continuous material transfer between parallel stations.

- Compact layout ideal for return-type or loop-type automation systems.

- Energy-efficient operation with regenerative braking (in advanced models).

- Reduced operator fatigue and improved process efficiency.

- Compatible with barcode scanners, sensors, and MES systems.

Application Areas

- Automotive & EV powertrain assembly lines.

- Electronics & PCB handling conveyors.

- Food and packaging lines.

- Metal casting, inspection, and heat-treatment lines.

- Plastic molding and robotic integration systems.