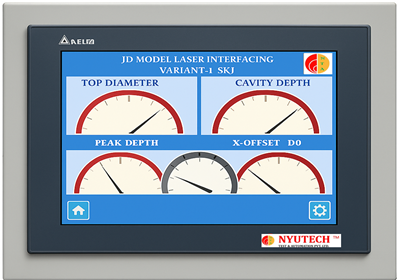

Nyutech designs and manufactures advanced gauging solutions that ensure accurate dimensional measurement and consistent quality control across production lines. Our automated gauging systems are engineered for reliability, repeatability, and seamless integration into manufacturing and inspection environments.

This semi-automatic gauging station is engineered for micron-level dimensional validation of precision components, designed to meet Tier-1 automotive and aerospace OEM quality standards. It ensures zero-defect manufacturing by integrating intelligent part validation, automated sensing, data traceability, and fool-proof Poka-Yoke mechanisms.

Key Functional Features:

Applications:

Gauging Solutions

Gauging Solutions

Gauging Solutions

Gauging Solutions