Nyutech is a leading leak testing machine manufacturer in Bangalore, specializing in custom-designed pneumatic and vacuum leak testing machines for automotive, EV, plastics, medical, and industrial applications.

We manufacture reliable, high-accuracy leak testing machines that integrate seamlessly into SPMs and automated production lines.

We are using all branded Leak Testing Devices in our machines but its always a choice to our customers which they prefer as per their standard requirements.

We have sound experiences in below mentioned leak testing devices such as

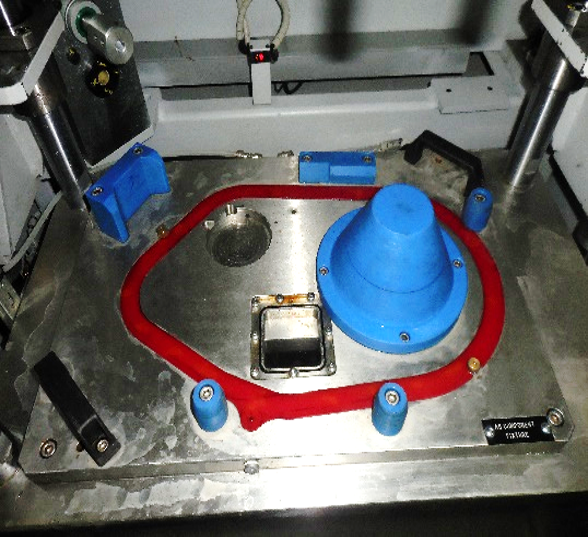

We at NYUTECH do leak test in both Air & Under Water medium. In Air medium we use 2 circuits such as Relative pressure method & Differential Pressure method devices to find out leakage in parts & In water medium we use to deep the component inside water which is inbuilt in machine followed by air input at required test pressure & check for any water bubbles are generating visually with in a time intervals.

Relative Pressure Method: In this method, the test specimen is filled with a predetermined pressure. After the filling time has elapsed, the test volume is sealed off. Following a stabilization time, during which temperature equalization takes place between the test specimen, testing equipment and test medium, actual testing commences. If the test specimen is leak, the pressure in the test volume will begin to fall. The difference in pressure is measured between the beginning and end of the test period and is subjected to rating. In this method, use is made of piezoresistive pressure sensors, whose range of measurement corresponds to the test-pressure range. This method is highly suitable for detecting minor to medium-sized leakages.

Differential Pressure Method: In this method the test specimen and a tight reference volume are filled with equal pressure. Afterwards they are both sealed off separately. After a stabilization time has elapsed, during which temperature equalization takes place between the test specimen, testing equipment and test medium, the actual process of testing commences. If the test specimen is leak, this will result in a difference in pressure between the test specimen and the reference volume, this then being measured and subjected to rating. In this method, use can be made of pressure sensors geared to a maximum accuracy regardless of the test pressure selected. This method is highly suitable for detecting minor leakages.

Leak Testing Machine Capabilities:

As a special purpose machine manufacturer in Bangalore, Nyutech integrates leak testing with automated loading, vision inspection, marking, data traceability, and conveyor systems.

This enables 100% in-line inspection without affecting takt time.