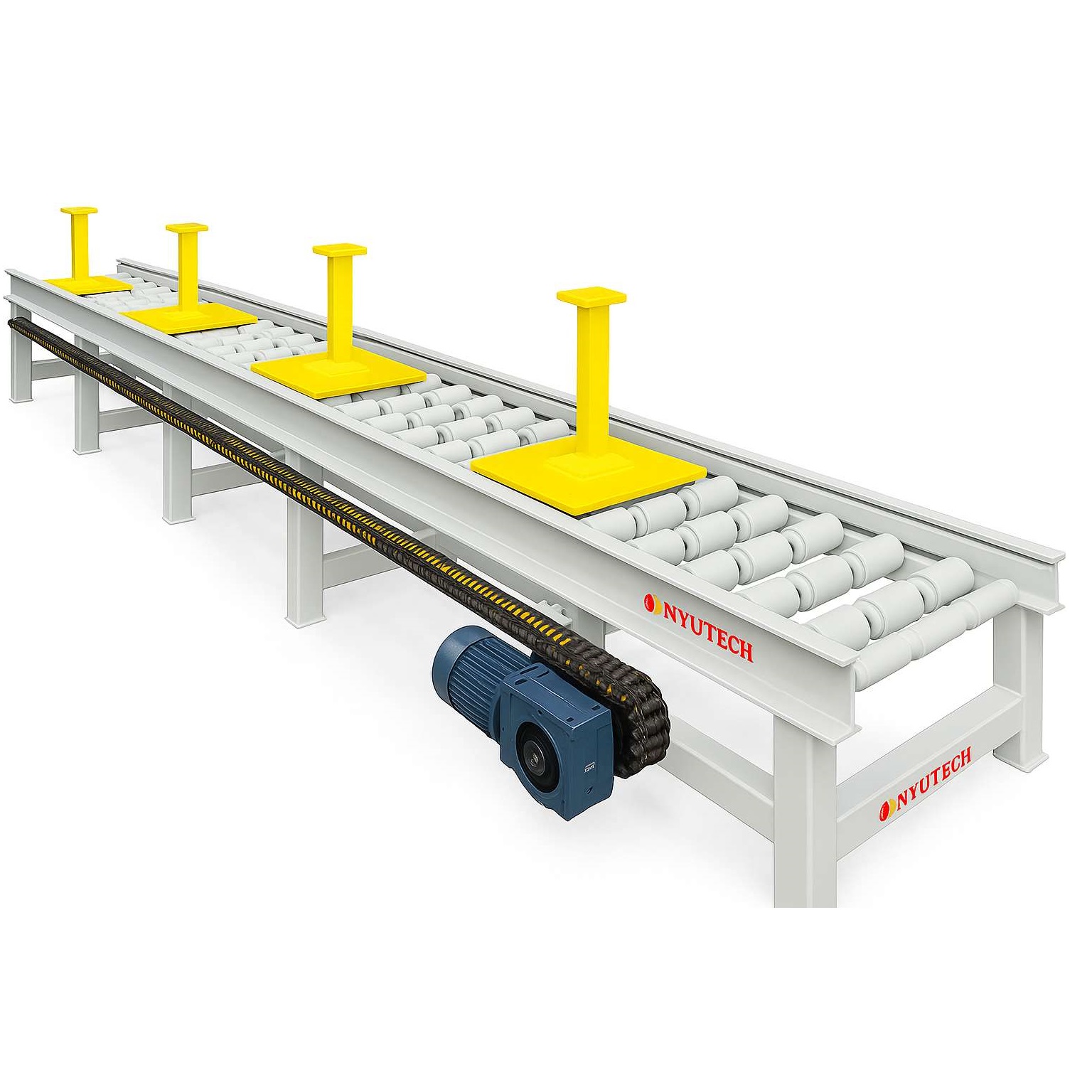

The Plastic Roller Conveyor is designed for smooth and efficient material transfer of lightweight components, bins, and trays in manufacturing and assembly environments. Its modular design ensures reliable operation with low noise, low friction, and minimal maintenance. The system integrates seamlessly with automated handling lines, offering flexible transport solutions for diverse industries.

Key Features

- Durable Plastic Rollers: High-strength acetal (POM) rollers for smooth, non-abrasive conveying of delicate parts.

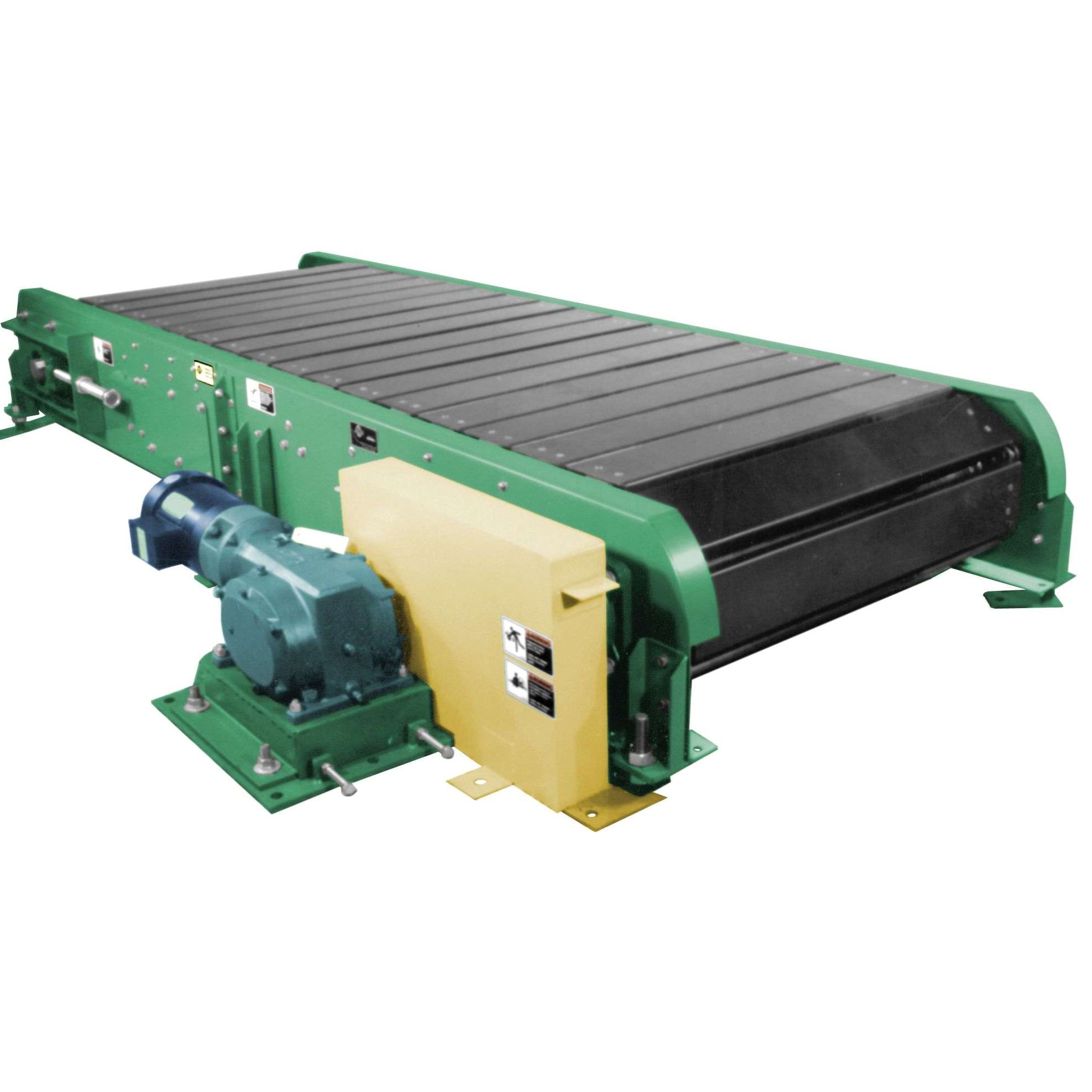

- Motorized Drive System: Integrated gear motor with VFD control ensures adjustable speed and consistent torque delivery.

- Sturdy Frame Construction: Fabricated steel structure with RAL 5010 powder-coated finish for long-term corrosion protection.

- Chain or Belt Drive: Dual chain or belt transmission for synchronized roller motion.

- Customizable Design: Length, width, roller pitch, and speed tailored to application requirements.

- Pneumatic Stopper (Optional): For automatic part positioning and accumulation control.

System Benefits

- Gentle handling of plastic bins, trays, and finished goods.

- Adjustable conveying speed for different process needs.

- Energy-efficient, low-maintenance operation.

- Easy integration with sensors, PLCs, and robotic systems.

- Ideal for 5-part batch movement (up to 10 kg total load) applications.

Application Areas

- Automotive sub-assembly lines.

- Electronic parts handling.

- Food and pharmaceutical packaging.

- Plastic molding and inspection stations.

- Warehouse and distribution conveyors.