Conveying Automation refers to the design and integration of automated material handling systems used to transport components, sub-assemblies, and finished products across different manufacturing or assembly stations.

It enables continuous, controlled, and efficient movement of materials, minimizing manual handling, improving safety, and ensuring high productivity.

Modern conveying systems are equipped with sensors, drives, PLC controls, and data interfaces to synchronize with robotic cells, testing machines, and data-traceability networks in Industry 4.0 manufacturing environments.

System Overview:

Conveying automation forms the backbone of every production line—linking mechanical assembly, testing, packaging, and inspection modules into a single integrated process flow.

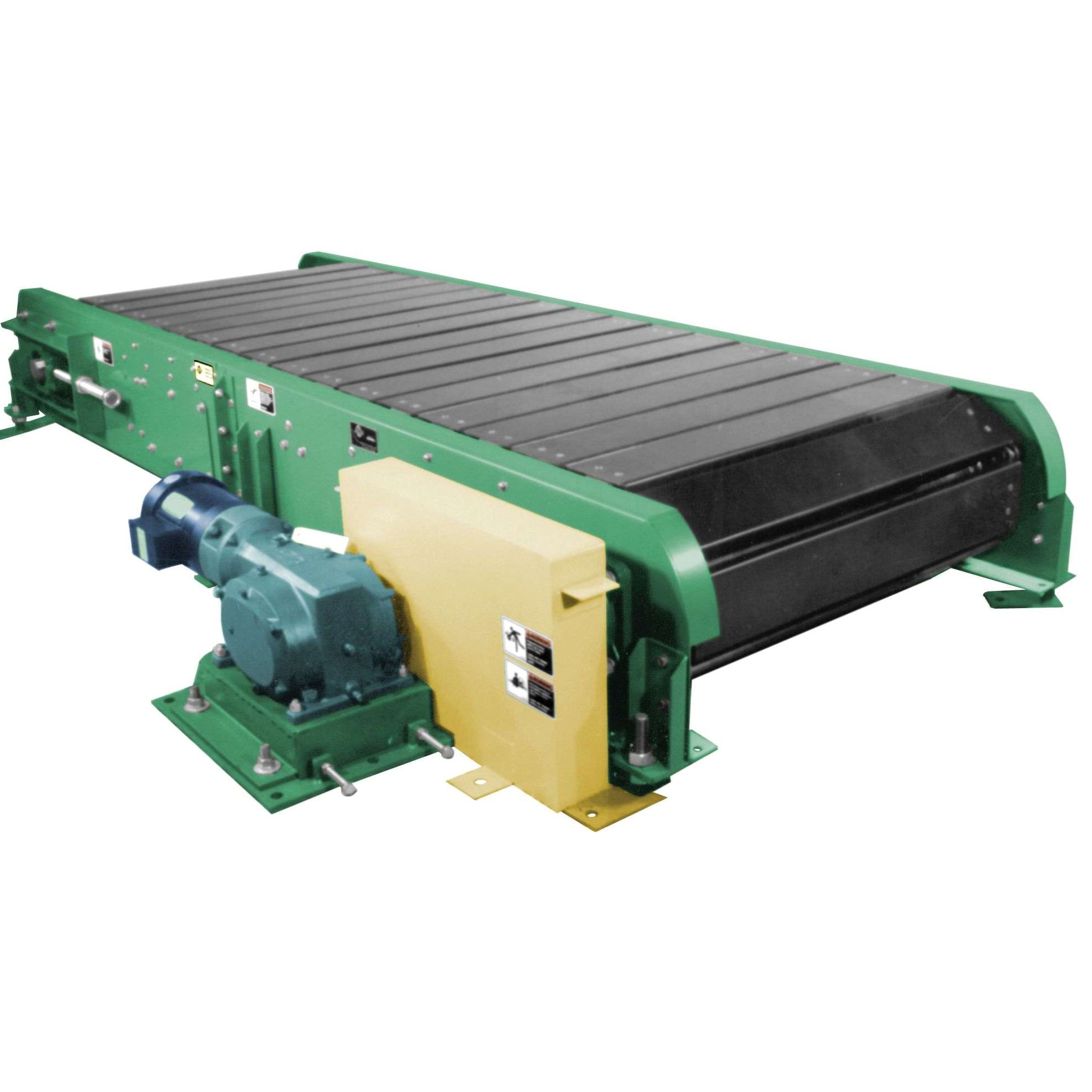

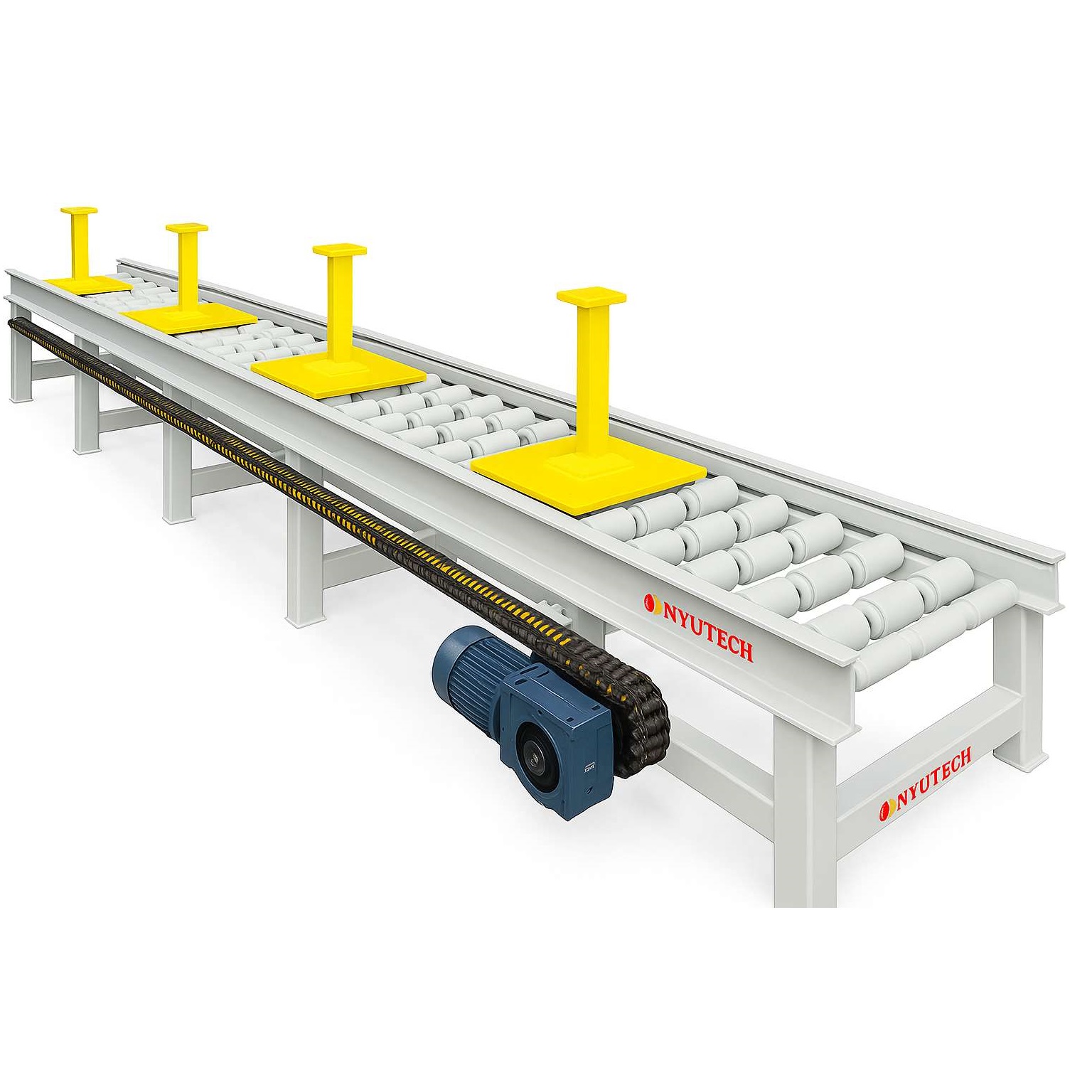

The system typically includes belt, roller, chain, or slat conveyors, customized for part geometry, weight, and environmental conditions (heat, dust, room, etc.).

Each conveyor is powered by servo, induction, or brushless DC drives, with precise control through variable-frequency drives (VFDs) or servo amplifiers.

Modern conveyors can communicate with central PLCs and MES systems for production status, error tracking, and preventive maintenance scheduling.

Key Features:

Multi-Machine Data Integration

- Modular Construction - Easily reconfigurable design with aluminum or steel frames.

- Automated Indexing - Servo/stepper-driven indexing for precise part positioning.

- Integrated Controls - PLC and HMI-based control with sensor feedback and emergency interlocks.

- Safety & Ergonomics - Meets ISO 10218 and EN 619 standards for operator safety.

- Scalability - Supports line expansion, additional stations, or vision inspection units.

- Smart Monitoring - Optional IoT modules for conveyor speed, motor health, and jam detection.

System Benefits:

- Continuous, reliable, and repeatable part flow between operations.

- Reduced human fatigue and improved ergonomic safety.

- High throughput with synchronized machine interaction.

- Compact layouts for optimal floor space utilization.

- Compatibility with robotic handling, AGVs, and MES traceability.

- Energy-efficient drive systems with regenerative braking (in advanced models).

Global Industry Compliance:

All conveyor systems are designed as per:

- ISO 3691 / EN 619 – Conveyor Safety Standards

- DIN 15201 / CEMA – Design & Performance Standards

- IEC 60204-1 – Electrical Safety & Control Panel Norms

- CE / RoHS Compliance – European Conformity and Environmental Standards

Application Areas:

- Automotive and EV powertrain assembly lines

- Electronics and PCB handling conveyors

- Food and pharmaceutical packaging lines

- Metal casting and heat-treatment systems

- Plastic molding and robotic integration lines

Conveying Automation

Conveying Automation

Conveying Automation

Conveying Automation

Conveying Automation

Conveying Automation